The efficient transfer of electrical power and signals is paramount in various industries, from automotive to telecommunications. At the heart of these connections lies wire harness assembly, a process that plays a critical role in ensuring reliability and performance. According to a report by MarketsandMarkets, the global wire harness market is projected to grow from USD 51.7 billion in 2021 to USD 81.1 billion by 2026, illustrating the increasing demand for streamlined electrical connectivity solutions. This growth can largely be attributed to the rising complexity of electrical systems and the need for efficient organization of wires, which wire harness assembly adeptly provides.

Wire harness assembly is not merely a support structure; it is integral to the functionality and safety of electronic systems. A well-designed wire harness minimizes the risk of electrical shorts, reduces installation time, and enhances overall product durability. The International Electrotechnical Commission (IEC) reports that approximately 30% of electrical failures in electronic devices stem from wiring issues, underscoring the importance of high-quality wire harness assembly in mitigating such risks. As industries continue to evolve with advanced technologies, the significance of proper wire harness assembly cannot be overstated, making it a crucial aspect of modern electrical connection strategies.

Wire harness assemblies are crucial components in various industries, including automotive, aerospace, and consumer electronics. They serve as vital conduits for electrical connections, ensuring reliable and efficient transmission of power and signals. Designed to bundle multiple wires and cables together, wire harnesses not only facilitate organization but also enhance the durability of electrical systems. According to industry reports, approximately 70% of electrical failures in machinery are attributed to wiring issues, highlighting the critical importance of selecting high-quality harness assemblies.

Understanding the functionality of wire harness assemblies requires recognizing their multifaceted role. They are engineered to withstand environmental stresses such as extreme temperatures, vibrations, and exposure to chemicals. This resilience extends the lifespan of electronic devices and reduces maintenance costs. A report from the Electrical Connector Association (ECA) indicates that implementing well-designed wire harness assemblies can lead to a 30% reduction in installation time and a significant decrease in material waste.

**Tips:** 1. When designing a wire harness assembly, consider utilizing color-coded wires for easy identification and troubleshooting. 2. Always perform thorough testing on prototypes to identify potential failure points before mass production. Investing time in the planning and design stages can save substantial costs and enhance the efficiency of your electrical connections.

Wire harness assemblies play a vital role in ensuring the efficiency of electrical systems across various applications. These assemblies facilitate organized and secure connections between multiple electronic components, reducing the risk of connectivity issues. By providing a streamlined network for conducting electricity, wire harnesses minimize the potential for signal interference and energy loss, ultimately leading to improved system performance and reliability.

When designing wire harness assemblies, it is important to consider factors such as wire gauge, insulation material, and layout. Opt for high-quality components to enhance durability and resist environmental factors that could lead to degradation. Additionally, ensure the layout is optimized to prevent potential short circuits and to allow for effective heat dissipation.

**Tips: Always label your wire harnesses clearly to simplify troubleshooting and maintenance. Additionally, test the assembly under real-world conditions to ensure that it meets operational requirements before finalizing the design. This proactive approach not only enhances efficiency but can save time and resources in the long run.**

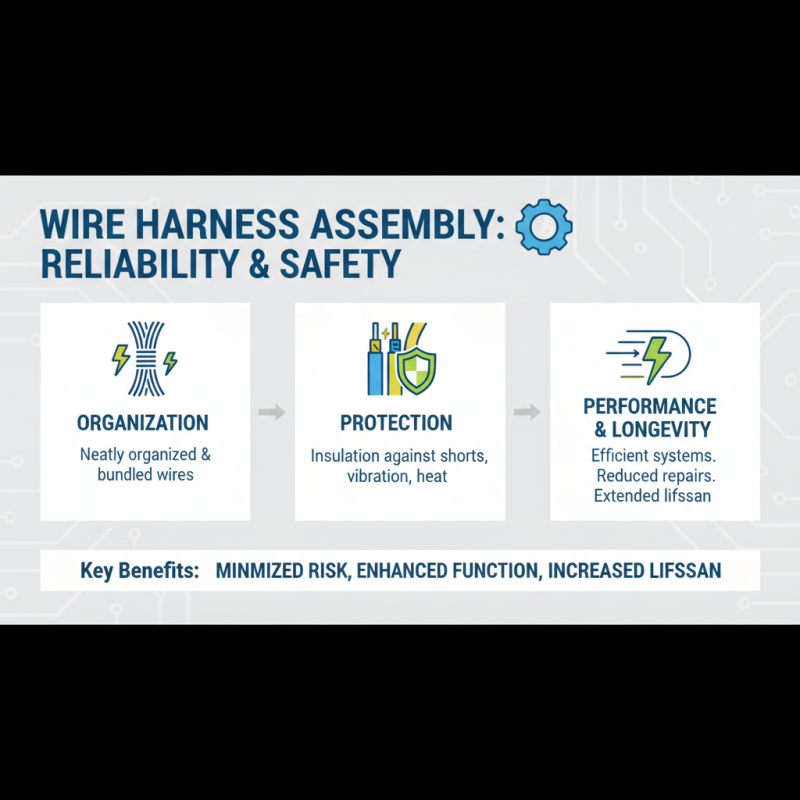

Proper wire harness assembly plays a vital role in ensuring the reliability and safety of electrical connections across various applications. A well-assembled wire harness is essential for minimizing the risk of short circuits, ensuring that electrical systems function correctly and efficiently. When wires are neatly organized, bundled, and insulated, they reduce the likelihood of accidental contact and damage from vibrations, heat, or environmental factors. This meticulous assembly not only enhances the overall performance of electrical systems but also extends their lifespan, reducing costly repairs and replacements.

Tips for effective wire harness assembly include selecting the right materials for insulation and protection, as well as implementing clear labeling for easy identification of connections. Avoiding wire abrasion is crucial, so using quality grommets and routing harnesses properly can greatly enhance safety. Additionally, regular inspections after assembly can help identify potential issues before they escalate, ensuring the longevity and reliability of the entire system.

By prioritizing proper wire harness assembly, manufacturers can create safer and more efficient electrical systems that meet the highest standards of reliability. Incorporating best practices into every assembly process is integral to reducing downtime and increasing trust in electrical connections, ultimately leading to improved performance in various applications.

In today's rapidly evolving technological landscape, the design and manufacturing of wire harnesses play a pivotal role in ensuring efficient electrical connections across various industries, including automotive, aerospace, and consumer electronics. According to a report by MarketsandMarkets, the global wire harness market is projected to grow from USD 54.5 billion in 2020 to USD 81.1 billion by 2025, driven by the increasing demand for lightweight materials and integrated technologies. This growth underscores the importance of meticulous design processes that facilitate optimal performance and reliability in electrical systems.

Key considerations in designing wire harnesses include the selection of appropriate materials and the optimization of geometric configurations. Engineers often utilize advanced simulations to predict performance under various conditions and to minimize electromagnetic interference—one of the critical factors impacting operational efficiency. Furthermore, adhering to industry standards such as IPC/WHMA-A-620 is vital, as these guidelines provide specifications for the manufacture and assembly of wire harnesses, ensuring consistency and quality. Research indicates that well-designed wire harness assemblies can reduce the risk of failures by up to 25%, demonstrating their critical role in enhancing the longevity and functionality of electrical connections.

This chart illustrates the key benefits of wire harness assembly, highlighting its crucial role in enhancing cost efficiency, time savings, safety, reduced downtime, and quality control in electrical connections.

Wire harness assemblies play a pivotal role across various industries by providing a reliable means of connecting electrical components. In the automotive sector, for instance, wire harnesses are essential for managing the intricate network of power and data required for modern vehicles. These assemblies ensure that all parts, from the engine to the infotainment system, communicate efficiently, contributing to enhanced safety features and improved driver experiences. Furthermore, as vehicles increasingly adopt advanced technologies such as electric powertrains, the demand for well-structured wire harness assemblies continues to rise.

In the aerospace industry, wire harness assemblies are equally important. They facilitate the connection of control systems and instrumentation, ensuring that aircraft operate smoothly and safely. Given the extreme environments and stringent safety requirements in this sector, wire harnesses must be engineered to withstand harsh conditions while maintaining optimal functionality. Additionally, in consumer electronics, wire harnesses help streamline the assembly process of devices like smartphones and laptops, enabling manufacturers to optimize space and improve connection reliability. Overall, wire harness assemblies are critical for ensuring the functionality and efficiency of electrical systems across multiple applications.

| Industry | Common Applications | Key Benefits |

|---|---|---|

| Automotive | Wiring for electrical systems, lighting, infotainment | Enhanced reliability, reduced installation time |

| Aerospace | Avionics, power distribution, communication systems | Weight reduction, improved safety, and functionality |

| Medical | Diagnostic equipment, surgical devices | Higher precision, compliance with safety standards |

| Consumer Electronics | Devices and appliances | Compact designs, improved performance |

| Industrial Machinery | Robotics, automation systems | Durability, efficient power management |

Precision Cable Assemblies

16830 Pheasant Drive

Brookfield, WI 53005

Phone: 262-784-7887

Fax: 262-784-0681