In today's fast-paced technological landscape, cable assembly power is crucial for successful projects. It serves as the backbone of electrical connectivity, ensuring that devices and systems operate efficiently. Many underestimate its importance, yet the right cable assembly can enhance performance significantly.

Consider the intricate designs of modern machines. They rely heavily on reliable cable assemblies to deliver power and data. A poor assembly can lead to malfunctions, delays, and increased costs. It's vital to invest time in selecting quality materials and designing robust connections. However, many projects still contend with subpar cable assemblies, often due to budget constraints. This tendency towards shortcuts may save money but can lead to significant issues down the line.

Integrating cable assembly power effectively demands attention to detail and foresight. Small choices in design and materials accumulate into larger impacts. Reflect on past projects—did you prioritize the right cable assembly? Identifying weaknesses in your previous experiences can lead to improved outcomes. Ultimately, recognizing the significance of cable assembly power could be the key to your project's success.

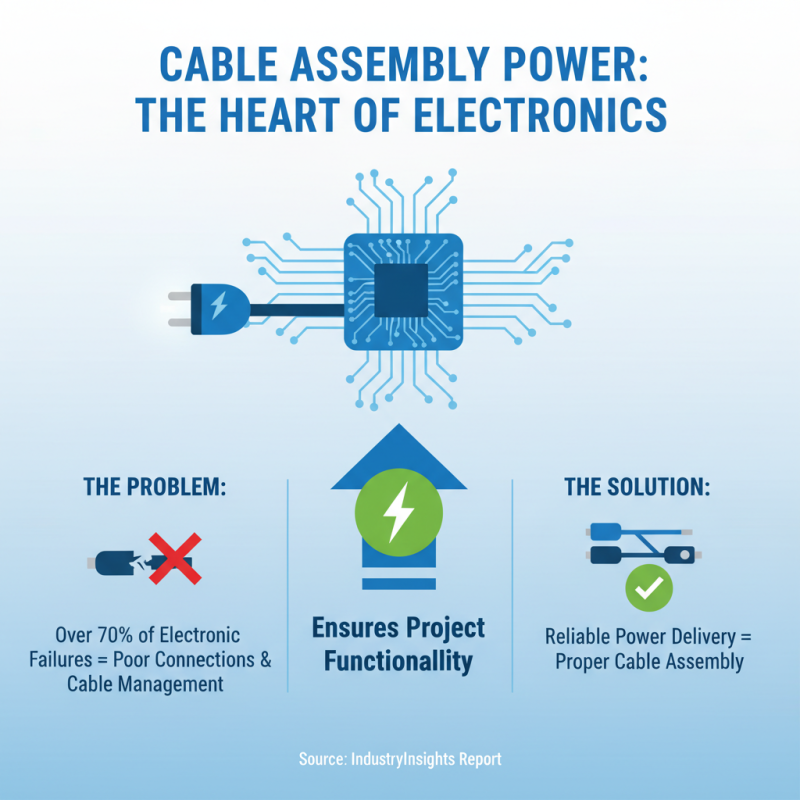

In modern electronic projects, cable assembly power plays a crucial role. A report by IndustryInsights indicates that over 70% of electronic failures stem from poor connections and cable management. Proper cable assembly ensures reliable power delivery. When power connections are subpar, project functionality suffers greatly.

Consider the rapid growth in sectors like renewable energy and automotive electronics. According to TechResearch, the global market for cable assemblies is expected to exceed $90 billion by 2025. This surge reflects the rising demand for efficient, high-quality power connections. However, not all projects prioritize robust cable assemblies. This oversight can lead to flickering devices or even system failures.

Improper assembly techniques are often a silent killer. A lack of attention to detail can result in shorts or overheating. Furthermore, many engineers underestimate the impact of environmental factors on cable performance. Over time, cables can degrade, affecting their reliability. For long-term project success, recognizing and addressing these issues is vital. Engaging in continuous improvement of cable assembly practices might be the key to avoiding costly errors.

High-quality cable assemblies are critical for many projects. They include various components that ensure efficiency and reliability. When choosing the right assembly, consider the connectors. They must be durable and compatible with your devices. Poor connections can lead to failures. Soldering quality is another key factor. A neat solder joint prevents overheating and ensures conductivity.

Insulation materials also play a vital role. They protect wires from damage and interference. Look for flexible and resilient materials. That way, assemblies can withstand movement and various conditions. Additionally, the overall design affects performance. A well-organized layout reduces clutter and makes troubleshooting easier. In contrast, tangled cables lead to confusion.

Reflecting on these components is crucial. A small oversight can cause major issues later. Ensure every detail is perfect. The right assembly could save time and prevent costly errors down the line. Quality matters in every aspect of a project's success.

Cable assembly power is critical in various projects. It ensures that components operate efficiently and safely. However, the performance of cable assemblies is influenced by several key industry standards. Understanding these standards can enhance your project’s reliability and longevity.

One important aspect is the wire gauge. Thinner wires may overheat, while thicker wires can be more rigid. Select the right gauge for your application to avoid these issues. Another factor is insulation type. Different environments demand different materials. For example, outdoor projects require UV-resistant insulation.

Tips: Regularly check your cable assemblies for wear and tear. This can prevent unexpected failures. It’s also wise to document the specifications of your cables. This practice fosters transparency and allows for easier troubleshooting.

Remember, not all cable assemblies are created equal. You may face challenges in meeting performance expectations. Each project has unique requirements. Always reassess your choices based on environment and usage. Prioritizing standards helps avoid mishaps down the road.

Cable assembly power plays a crucial role in device reliability and efficiency. Poor cable assembly can lead to weak connections. This affects not just power flow but also device lifespan. When devices struggle with inadequate power, performance issues arise. Overheating and premature failures become common.

To ensure reliability, proper cable selection is key. Use high-quality materials to withstand wear. Consider the environment where the device operates. Harsh conditions may require reinforced assemblies. Frequent checks can prevent future problems. Regular visual inspections help spot wear and tear early, reducing downtime.

Don’t overlook the importance of testing. Simulate operational conditions to find weaknesses. Inadequate power supply can disrupt entire systems. Aim for detailed documentation to track changes over time. Learn from past mistakes to improve future designs.

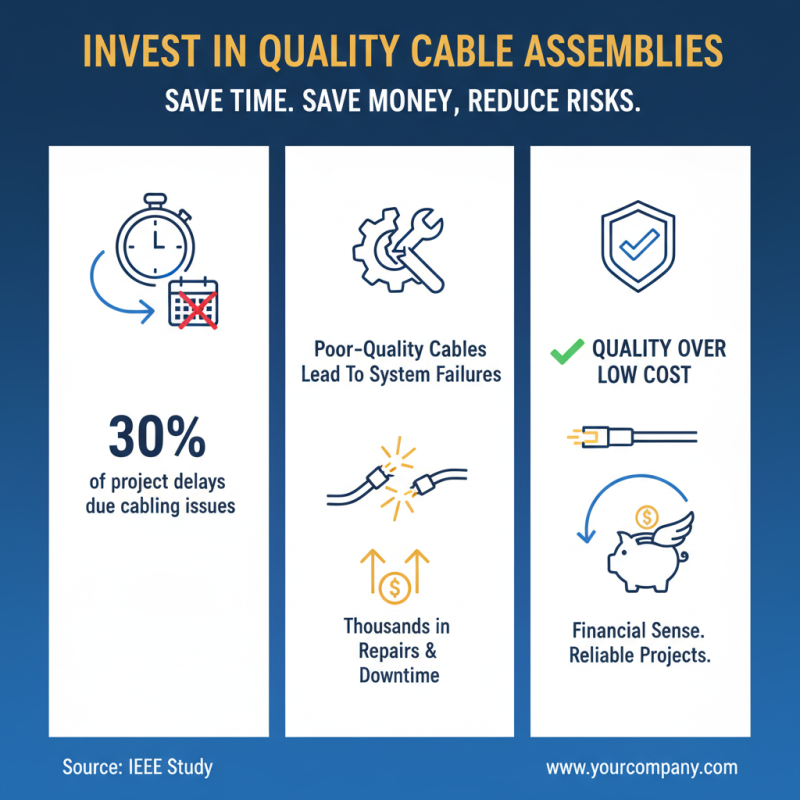

Investing in quality cable assemblies can significantly impact project budgets and timelines. According to a study by the Electrical and Electronics Engineers (IEEE), over 30% of project delays result from cabling issues. Poor-quality cable assemblies often lead to system failures, costing companies thousands in repairs. It makes financial sense to prioritize quality over low initial costs.

The long-term benefits of robust cable assemblies are evident. A report by BSRIA indicates that high-quality cables improve efficiency by up to 25%. This efficiency translates into reduced energy costs over time. Companies that invest in reliable assemblies often enjoy fewer disruptions and lower maintenance costs.

However, the upfront investment can be daunting. Many hesitate to allocate a budget for quality components. Yet, the hidden costs of cheap alternatives often outweigh the initial savings. Failing to recognize this can lead to repeated costs. Companies must weigh immediate savings against potential future losses. Consider the overall impact on project timelines and labor. The choice is clear: quality always pays off in the end.

Precision Cable Assemblies

16830 Pheasant Drive

Brookfield, WI 53005

Phone: 262-784-7887

Fax: 262-784-0681