In today’s high-tech world, the role of cable assembly design is critical. It connects devices, ensures functionality, and impacts overall performance. Effective cable design solutions are vital in various industries, from telecommunications to automotive sectors. Engineers face many challenges, such as signal integrity, heat management, and space constraints. Each element requires careful consideration.

Creating an effective cable assembly design involves a mix of creativity and technical knowledge. Mistakes in design can lead to costly errors or product failures. It is essential to evaluate materials, connectors, and layout early in the process. Failing to account for environmental factors, such as moisture or temperature variations, can hinder performance.

Regular feedback and testing throughout the design phase cannot be overlooked. Engineers must remain open to adjustments. Not every design will succeed on the first try. Reflection on previous designs often leads to improved solutions. Emphasizing collaboration among team members will create innovative ideas. Ultimately, thoughtful cable assembly design enhances product reliability and user satisfaction.

When diving into cable assembly design, it's essential to grasp the fundamental principles. Effective designs start with understanding the purpose and environment of the assembly. What are the specific requirements? Are there space limitations? These factors significantly influence your approach. You must consider bend radii, strain relief, and cable length. Each detail matters.

A common mistake is neglecting proper benchmarking. Use existing designs as a reference. Analyze them critically. What worked? What didn’t? This reflection can guide improvements. Another key aspect is material selection. The type of insulation and connectors you choose can affect durability and performance. Often, there's a balance between cost and quality that needs careful evaluation.

Testing is another vital phase. Many designs appear perfect in theory but fail in real-world applications. Conducting thorough simulations and physical tests can prevent costly errors. The design process is iterative. Expect setbacks and use them as learning opportunities. Embrace the imperfections; they can lead to innovative solutions in your cable assembly designs.

| Dimension | Specification | Material | Application |

|---|---|---|---|

| Length | 1.5 meters | PVC | Industrial Equipment |

| Insulation Diameter | 6 mm | TPE | Medical Devices |

| Connector Type | M12 | Nickel Plated | Automotive |

| Wire Gauge | AWG 18 | Copper | Consumer Electronics |

| Temperature Rating | -40°C to 85°C | Silicone | Aerospace |

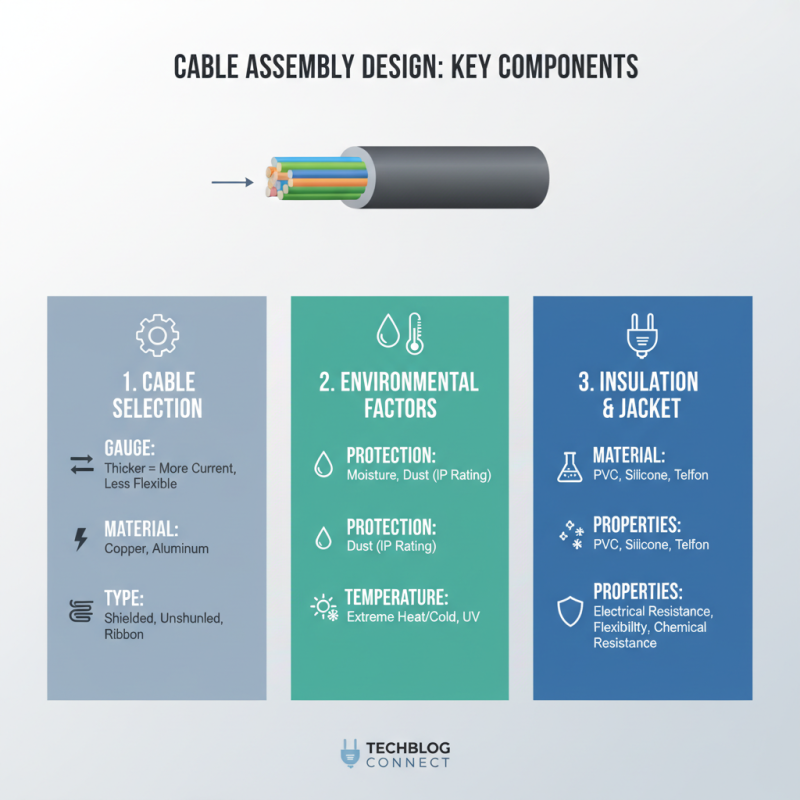

When designing cable assemblies, identifying key components is crucial for success. Start with the cable itself. Selecting the right gauge is vital. A thicker cable can carry more current but may be less flexible. Consider the environment where the assembly will be used. Is it exposed to moisture or extreme temperatures? These conditions can impact your choice of insulation.

Connectors are another important element. They must match both the cable size and the application’s requirements. Poorly matched connectors can lead to failures. Moreover, it’s essential to assess the overall layout of the assembly. A cluttered design can cause interference and make repairs challenging. Sometimes, a simple design may yield better performance than a complex one.

Don’t overlook the importance of strain relief. Proper strain relief prevents damage during installation and use. However, many designs neglect this aspect. It’s easy to focus on aesthetics and overlook functionality. Regular reviews and testing can reveal overlooked issues in your design. It's a learning process that requires attention to detail and an open mind.

Designing effective cable assembly solutions requires careful consideration of functionality. Excellent designs meet user needs while ensuring reliability. According to the International Electrotechnical Commission, around 30% of electronic failures result from poor cable management. Therefore, understanding the application is essential for durability.

One tip is to prioritize the environment where cables will be used. Factors like temperature and exposure to chemicals can impact performance. Strain relief is another critical aspect. When overlooked, it can lead to premature cable failure. Regular testing helps ensure designs hold up under various conditions.

A common mistake is to underestimate the complexity of assembly. Complex assemblies might seem appealing but can complicate manufacturing processes. Simplifying designs can enhance both reliability and cost-effectiveness. Aim for a balance between functionality and ease of production. Finding this balance often involves trial and error. Frequent revisions based on real-world feedback can lead to continuous improvement.

Testing and quality assurance in cable assembly designs are crucial for ensuring performance and reliability. According to industry reports, up to 70% of cable failures occur due to design flaws or inadequate testing. To prevent these issues, manufacturers must adopt a robust testing regimen. This should include both functional and environmental tests. Common tests include thermal cycling, vibration testing, and electrical continuity checks. Each test simulates real-world conditions that cables will face.

Moreover, implementing automated testing systems can enhance accuracy and efficiency. These systems can considerably reduce human error. A study shows that companies using automated systems have seen a 30% reduction in production defects. However, not all manufacturers prioritize these practices. Some may overlook thorough testing to cut costs, potentially leading to significant long-term issues. Inadequate quality assurance can lead to recalls and damage to reputation.

Documentation also plays a crucial role. Detailed records of testing procedures and results are essential for identifying patterns in failures. Many manufacturers struggle with keeping comprehensive records. This gap can hinder troubleshooting and improvement efforts. Establishing a culture of accountability and continuous improvement is vital. It's not just about passing tests; it's about understanding the entire process to deliver reliable cable assemblies.

The future of cable assembly technologies is evolving rapidly. Innovations in materials and manufacturing processes are paving the way for enhanced performance. According to recent market reports, the global cable assembly market is projected to reach $224 billion by 2027, growing at a CAGR of 6.3%. This growth will influence various industries, including automotive and telecommunications.

New materials, like lightweight composites, are gaining traction. These materials offer better durability and flexibility. However, adapting to these innovations can be a challenge for some manufacturers. Many still rely on traditional materials. Additionally, the push for more sustainable options is also gaining momentum. Some companies struggle with implementing eco-friendly practices without sacrificing quality.

Automation and robotics are key trends in the manufacturing process. These technologies increase efficiency but come with a learning curve. Data suggests that automation can improve production speed by up to 30%. However, this transition can lead to skill gaps in the workforce. Companies must invest in training to bridge this gap effectively. As the industry pushes forward, reflecting on these trends will be crucial for long-term success.

Precision Cable Assemblies

16830 Pheasant Drive

Brookfield, WI 53005

Phone: 262-784-7887

Fax: 262-784-0681