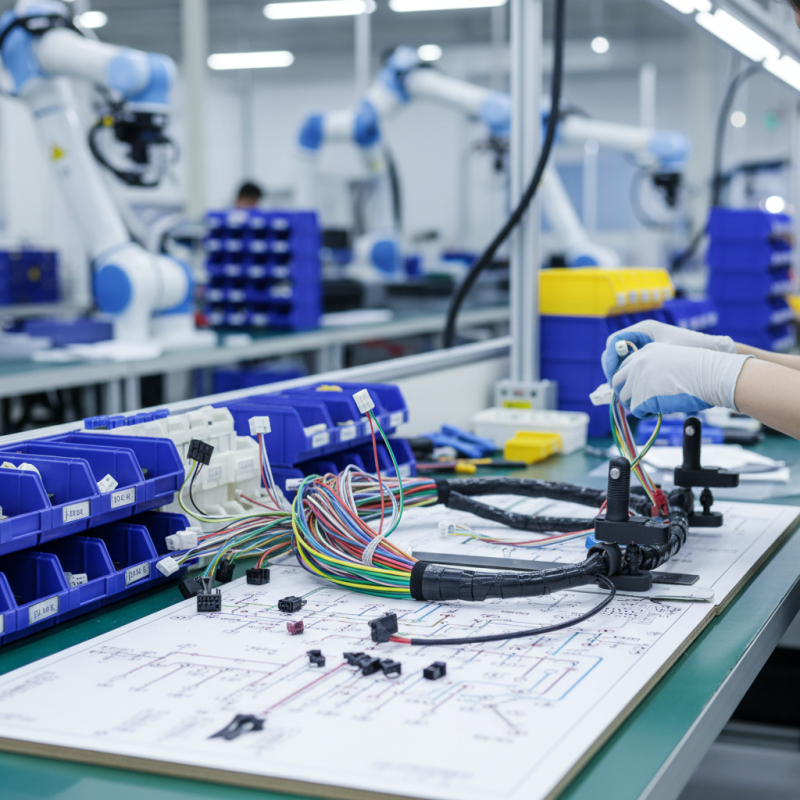

The assembly of electrical harnesses is critical in today's technology-driven world. A study by MarketsandMarkets indicates that the global electrical harness market is expected to reach $196.7 billion by 2025, showcasing continuous growth. This surge emphasizes the necessity for efficient assembly processes.

Effective electrical harness assembly not only reduces production costs but also enhances product reliability. However, achieving optimal assembly involves nuanced attention to detail. Many manufacturers overlook the significance of thorough training for assembly line workers. Proper techniques in organizing components can dramatically impact efficiency.

Despite advancements in technology, challenges persist. Common issues include misalignment of wires and improper connections, which lead to failures. Considering industry statistics, around 10% of wiring harnesses face rework due to these errors. Continuous improvement in assembly practices is essential for maintaining industry standards and ensuring safety.

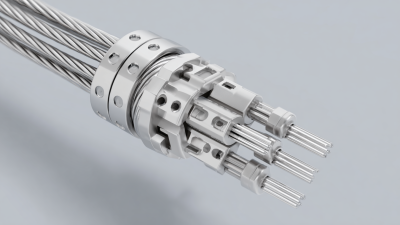

Electrical harnesses are crucial for organizing and protecting electrical wires. They simplify the connection of circuits in various applications. Understanding their structure is essential to making effective assemblies. Each harness consists of wires, connectors, and insulating materials. These elements together create a safe pathway for electrical flow.

When assembling an electrical harness, attention to detail is vital. Choose the right gauge wires for the intended current load. Inadequate sizing can lead to overheating. Ensure that connectors fit snugly. Loose connections may cause intermittent failures. It's also important to properly route the wires. Poor organization can lead to wear and tear over time.

Creating a prototype can help identify flaws before final assembly. You might notice areas where wires rub against sharp edges. Consider adding protective sheathing in those locations. Testing the assembly can reveal other issues, like incorrect pin placement. Reflect on these aspects during the assembly process. This critical evaluation can enhance the overall quality of the harness.

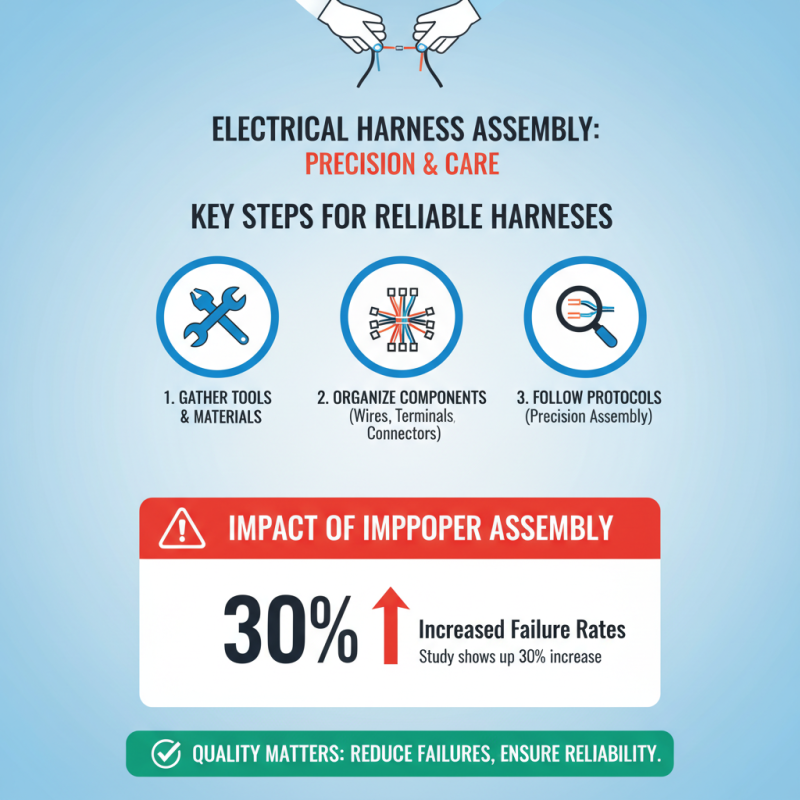

When assembling an electrical harness, having the right tools and materials is crucial. Start by gathering cutting tools. A wire cutter and stripper are essential for trimming and preparing the wires. Ensure they are sharp for a clean cut. Don't forget to have a pair of pliers ready. They will help manipulate connectors and secure the wires. Sometimes, a good grip can make a difference in the assembly process.

Next, consider the wiring itself. Select wires based on the electric capacity and environment they will be used in. Having various colors helps prevent confusion. It’s also a good idea to have heat shrink tubing on hand. This provides insulation and protection. However, ensure that it fits the wire size correctly. An inadequately sized tube can cause issues down the line.

Lastly, don’t overlook the connectors. They must match the specific requirements of your project. If you make a mistake here, it can lead to functionality problems. Having a tester is also beneficial to check for continuity once the harness is assembled. This process can be tedious, prompting some frustration. Reflecting on these challenges can improve your next assembly.

Assembling electrical harnesses requires precision and care. Each harness consists of wires, terminals, and connectors, all neatly organized. The process often begins with gathering tools and materials. A study showed that improper assembly can increase failure rates by up to 30%. This highlights the importance of following established protocols.

Begin by measuring and cutting wires to the right lengths. Each wire must fit perfectly to avoid shorts. Stripping the insulation is crucial too. Too much or too little can lead to connectivity issues. After stripping, crimp connectors onto the wires. This step is often rushed, leading to weak connections. According to industry reports, 25% of harness failures can be traced back to poor crimp techniques.

Next, organize the wires according to the schematic. Labeling is essential. Without proper labels, mistakes are common. Often, technicians overlook this step, resulting in confusion during installation. Finally, carefully secure the harness with ties or heat shrink tubing. Neglecting this can lead to damage. Industry surveys suggest that a well-assembled harness has a reliability rate of over 95%.

Assembling an electrical harness requires attention to detail. Many mistakes can occur during this process. According to industry research, nearly 30% of harness failures stem from improper assembly practices. It's crucial to prioritize accuracy while wiring and connecting components.

One common error is overlooking wire strain relief. Proper strain relief prevents damage to the wiring. Skipping this step may lead to harness failures later, as stress on wires can cause shorts or breakage. In fact, reports show that inadequate strain relief can increase maintenance costs by up to 20%.

Another frequent mistake is neglecting to label wires. Many assemblers assume they will remember the connections, but this often leads to confusion. Clear labeling can save hours during installation or troubleshooting. A survey highlighted that 40% of assembly teams faced delays due to misidentified wires, emphasizing the importance of organization in the assembly process.

This chart illustrates the common errors made during the assembly of electrical harnesses, highlighting the frequency of each mistake.

Testing and quality assurance are crucial for completed electrical harnesses. According to industry reports, up to 30% of wiring failures result from poor quality control. Implementing rigorous testing protocols can significantly reduce these numbers. Ensuring harnesses meet safety and performance standards is vital. A well-tested harness can prevent costly downtimes and enhance overall system reliability.

One effective testing method is thermal imaging. This technique identifies potential faults such as shorts or open circuits. Identifying issues early can save time and resources. Regular audits and inspections can keep quality in check. Each harness should undergo electrical testing under real-world conditions. This practice ensures it will perform effectively once integrated into final products.

Tips: Always document testing results meticulously. This data helps in future troubleshooting. Consider a feedback loop from your testing process. This reflection can highlight areas for improvement. Also, train your team regularly on the latest testing techniques. Knowledge is key to maintaining high standards in harness assembly.

Precision Cable Assemblies

16830 Pheasant Drive

Brookfield, WI 53005

Phone: 262-784-7887

Fax: 262-784-0681