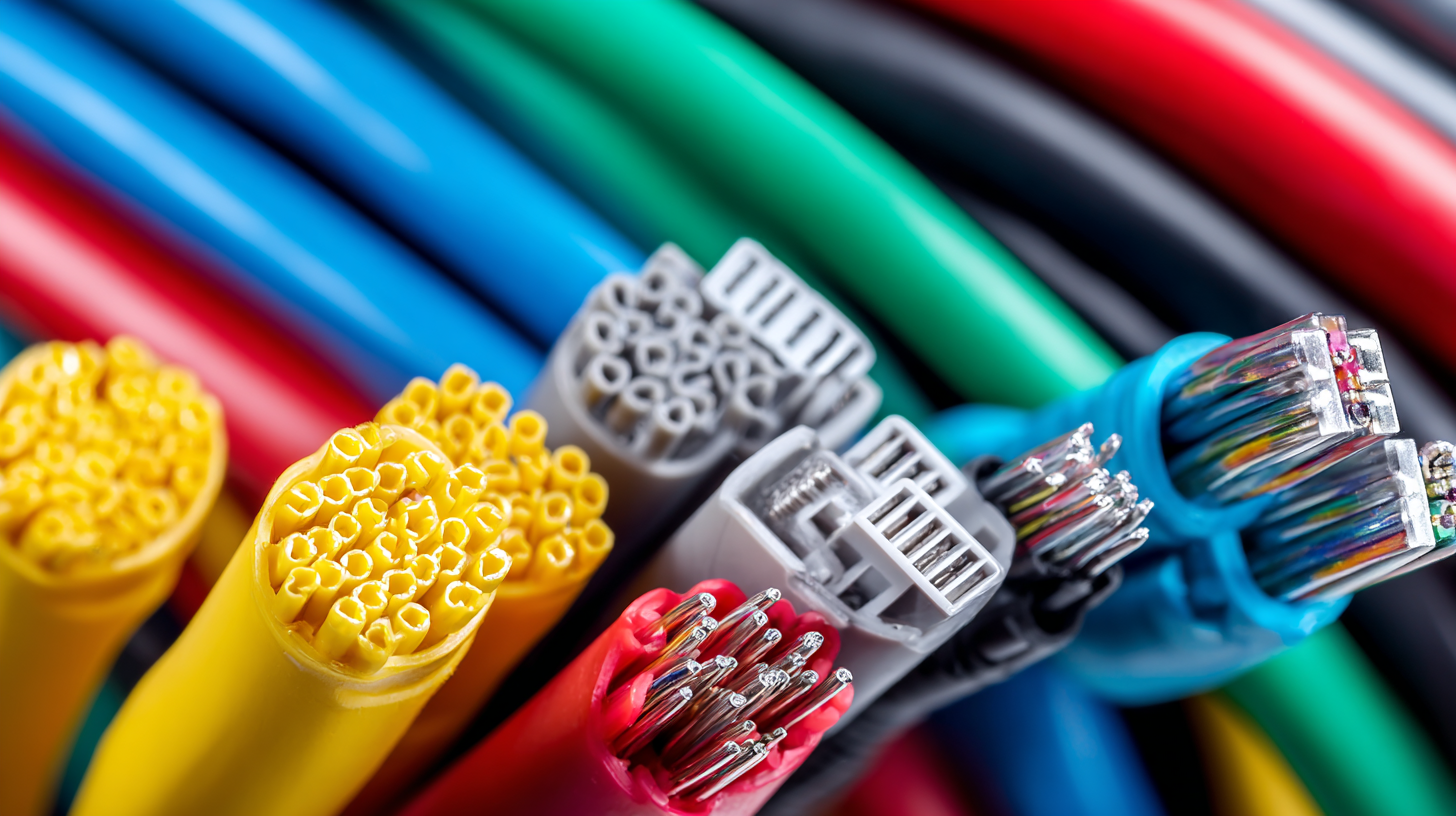

When embarking on a new project, whether it be in the realm of electronics, telecommunications, or industrial applications, one of the crucial components that often gets overlooked is the cable assembly. Selecting the best cable assembly is not merely a matter of picking a random product off the shelf; it requires a careful evaluation of various factors to ensure compatibility, efficiency, and reliability for your specific needs. This ultimate checklist aims to guide you through the essential considerations when choosing the ideal cable assembly for your project, helping you avoid common pitfalls and make informed decisions. From understanding the different types of cables and connectors to assessing the environmental factors that could impact performance, we will explore the key elements that will lead you to select the best cable assembly tailored to your unique requirements.

When selecting the best cable assembly for your project, understanding the key criteria for quality is paramount. Firstly, consider the environmental conditions in which the cable will operate. For instance, applications like offshore renewable energy systems require cable assemblies that can withstand harsh conditions and maintain structural integrity. Identifying these environmental factors early on can prevent unforeseen failures and ensure reliable performance.

Additionally, recent technological advancements have introduced specifications such as low-thermal-conductivity materials for cryogenic applications, which are essential in fields like quantum computing. Evaluating the materials used in cable assemblies is critical for ensuring that they meet the operational requirements of your project. Look for assemblies that incorporate innovative materials and manufacturing techniques to guarantee durability and performance. As the industry evolves, staying informed about new developments in cable technology can significantly impact the success of your project.

This bar chart illustrates the key criteria to consider when selecting a quality cable assembly. The criteria include Performance, Durability, Flexibility, Cost, and Customization.

When embarking on the journey of selecting the best cable assembly for your project, a crucial initial step is researching potential suppliers. Start by identifying what to look for in suppliers – quality certifications, production capabilities, and past project experience are foundational criteria. According to a recent procurement insights report, effective supplier relationships can lead to a 15% increase in project efficiency. It’s essential to evaluate their track record and innovation capacity, especially as technology continues to evolve rapidly.

Furthermore, leveraging resources like government procurement platforms can streamline your search for reliable suppliers. Engaging with certified suppliers fosters better negotiation outcomes and enhances collaboration, as highlighted in studies demonstrating that transparent communication can significantly strengthen buyer-supplier dynamics. Be sure to consider sustainability practices, as the shift towards eco-friendly operations is increasingly important—research indicates that 79% of businesses prioritize sustainability in supplier partnerships. With thorough research and a strategic approach, you can build a strong foundation for your cable assembly project.

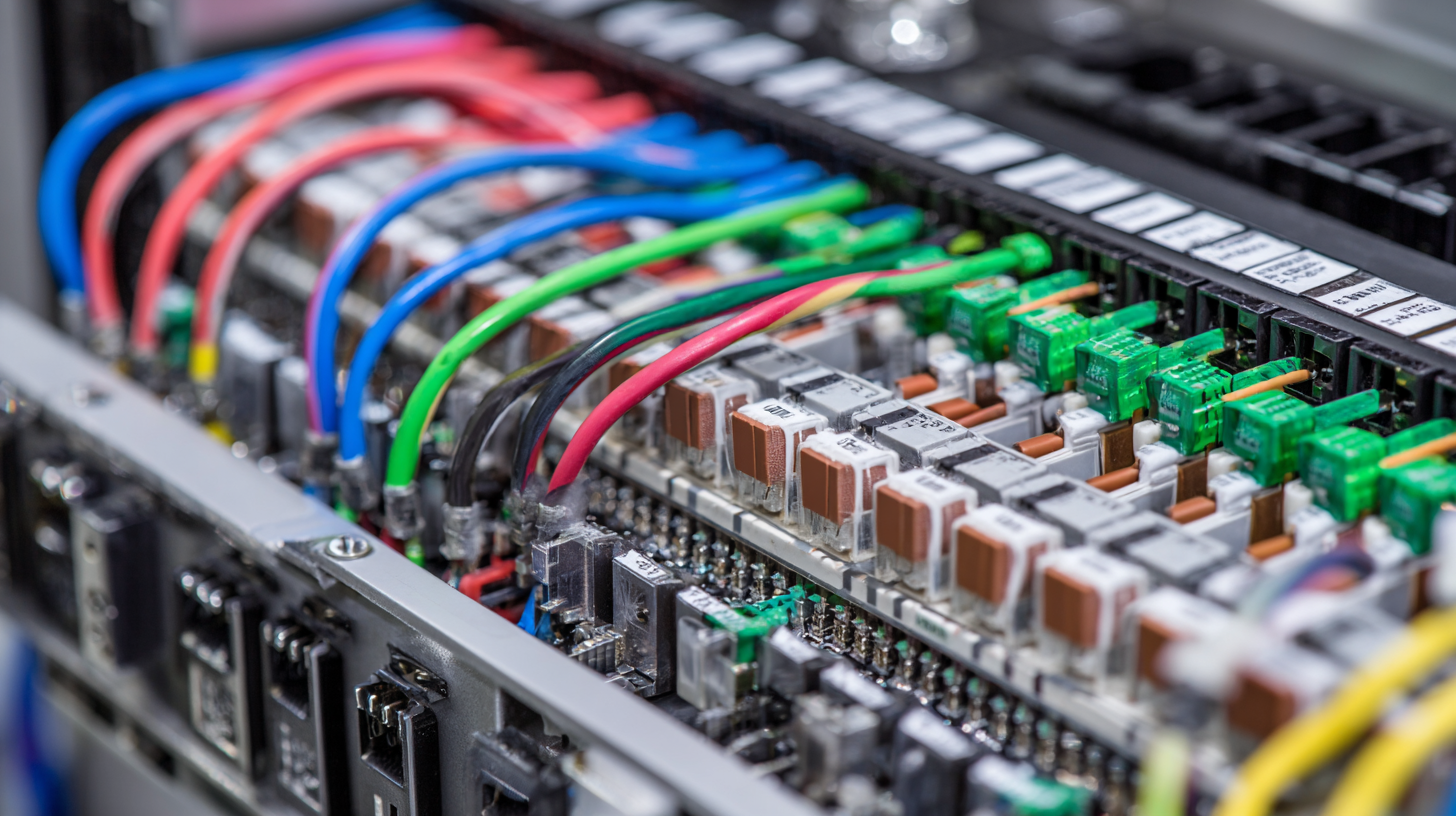

When selecting the best cable assembly for your project, evaluating supplier credentials is essential. Certifications play a critical role in ensuring that the products meet industry standards and quality benchmarks. Look for suppliers with ISO certification, as this indicates their adherence to strict quality management systems. Additionally, certifications specific to your industry can be beneficial. For example, UL listed cables assure safety and reliability, particularly for electrical applications.

When assessing a supplier's reputation, it's wise to seek out customer reviews and testimonials. A supplier with a proven track record is likely to deliver quality products consistently. Don't hesitate to ask for references from past clients to understand their experiences.

Tip 1: Always verify the supplier's certifications with the issuing organizations to ensure that they are up to date. This not only demonstrates the supplier's commitment to quality but also helps mitigate risks associated with subpar products.

Tip 2: Consider the supplier’s industry experience. A well-established provider with years of experience will have a better understanding of industry regulations and standards, ensuring that your cable assembly is compliant with necessary guidelines.

When selecting the best cable assembly for your project, understanding customization options and lead times is crucial. In a rapidly evolving market, customization allows companies to tailor their products to meet specific requirements, enhancing performance and efficiency. According to industry reports, the Electronic Contract Assembly market is projected to witness a compound annual growth rate (CAGR) of over 10.3% from 2025 to 2032, indicating a robust demand for bespoke solutions. This growth underscores the need for manufacturers to offer versatile cable assembly options that can adapt to varied applications while maintaining high quality and reliability.

Lead times are equally important in the decision-making process. Companies should assess how quickly suppliers can provide customized cable assemblies to meet project deadlines. As the market expands, the ability to deliver timely solutions will significantly impact competitiveness. Efficient supply chain management can help reduce lead times, allowing businesses to respond swiftly to market demands. Thus, careful evaluation of customization capabilities alongside lead times will ensure you select the ideal cable assembly that aligns with both your technical requirements and project timeline.

When selecting the best cable assembly for your project, understanding the pricing structures and cost-effectiveness in cable sourcing is crucial. Cable assemblies can vary widely in price, influenced by factors such as materials, manufacturing processes, and customization options. Typically, the cost can be broken down into raw materials, labor, overhead, and profit margins. By comprehensively analyzing these components, you can make informed decisions that align with your budget while ensuring quality.

Moreover, evaluating cost-effectiveness involves more than just looking at the initial price tag. It’s essential to consider the long-term value of the cable assembly, including durability, reliability, and performance in your specific application. Investing in a higher-quality assembly may incur a greater upfront cost but can lead to significant savings over time, reducing the need for replacements and minimizing downtime. By weighing these aspects, you ensure that you choose a cable assembly that not only meets your immediate project needs but also supports your overarching operational goals effectively.

| Criteria | Description | Estimated Price Range | Cost-Effectiveness Rating |

|---|---|---|---|

| Cable Type | Choose from various types, such as coaxial, optical fiber, and twisted pair. | $0.30 - $5.00 per meter | High |

| Connector Type | Select connectors best suited for the application, such as DB, RJ, or custom connectors. | $0.50 - $10.00 each | Medium |

| Volume Discounts | Consider potential savings when ordering in bulk. | Varies by supplier | High |

| Lead Time | Assess the time it takes for production and delivery. | 2 weeks - 8 weeks | Medium |

| Compliance Standards | Ensure assemblies meet relevant industry standards (e.g., RoHS, UL). | N/A | High |

| Customization Options | Evaluate the ability to customize cable assemblies for specific needs. | $1.00 - $20.00 extra | Variable |

Precision Cable Assemblies

16830 Pheasant Drive

Brookfield, WI 53005

Phone: 262-784-7887

Fax: 262-784-0681