In today's rapidly evolving manufacturing landscape, cable assembly plays a pivotal role in ensuring operational efficiency and product reliability. According to a report by MarketsandMarkets, the global cable assembly market is projected to reach $200.1 billion by 2025, growing at a CAGR of 6.2% from 2020. This growth is indicative of the increasing demand for high-quality, customized cable assemblies that meet the diverse needs of various industries, including aerospace, automotive, and consumer electronics. As manufacturers strive for greater automation and connectivity, the importance of robust cable assemblies cannot be overstated. They not only facilitate seamless communication between electronic components but also enhance the overall performance and safety of manufacturing systems. In this blog, we will explore seven compelling reasons why cable assembly is essential for your manufacturing success, providing insights that underscore its critical value in today’s competitive market.

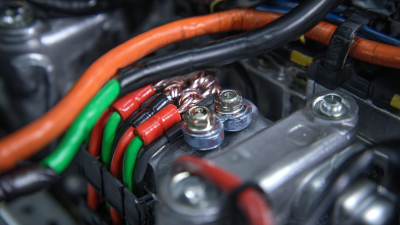

In modern manufacturing operations, reliable connections play a pivotal role in ensuring efficiency and productivity. Cable assemblies serve as the backbone of these connections, linking various components and systems seamlessly. When machines and systems communicate effectively through high-quality cable assemblies, manufacturers can avoid costly downtimes caused by communication failures. Each reliable connection not only enhances the overall functionality of the manufacturing process but also plays a significant role in maintaining safety standards.

Moreover, the importance of durability and resilience in cable assemblies cannot be overstated. In a manufacturing environment, equipment is often subject to vibrations, temperature fluctuations, and other challenging conditions. High-quality cable assemblies are designed to withstand these stresses, ensuring that connections remain intact and consistent over time. Prioritizing reliable connections ultimately leads to better product quality, more efficient operations, and a stronger competitive edge in the market.

In today's competitive manufacturing landscape, the cost-effectiveness of quality cable assemblies plays a pivotal role in ensuring operational efficiency and profitability. By investing in well-designed cable assemblies, manufacturers can streamline their production processes, reduce downtime, and ultimately cut operational costs. High-quality cable assemblies are designed to meet specific industry standards, ensuring they can withstand the rigors of the manufacturing environment while providing reliable performance over time.

Moreover, the long-term savings garnered from using quality cable assemblies extend beyond mere production costs. The durability and reliability of these assemblies lead to fewer maintenance issues and a reduced need for replacements. This not only facilitates smoother operations but also allows businesses to focus on innovation and growth rather than constantly addressing system failures. In a sector where precision and reliability are paramount, choosing the right cable assembly can be a strategic decision that directly influences a manufacturer’s bottom line. Investing in quality cable assemblies is not just a cost but a pathway to enhancing overall productivity and success in today's fast-paced market.

Custom cable assemblies play a pivotal role in enhancing product performance across various manufacturing sectors. According to a report by Research and Markets, the global market for cable assemblies is projected to reach USD 120 billion by 2025, primarily driven by the increasing demand for efficient connectivity solutions in high-performance applications. These assemblies not only provide reliable electrical connections but are also tailored to meet specific environmental and technical requirements, which can significantly reduce downtime and improve operational efficiency.

Furthermore, the importance of custom cable assemblies extends to their ability to optimize space and weight within products. A study conducted by Mordor Intelligence indicates that manufacturers can achieve up to a 30% reduction in weight by using specialized, lightweight cable assemblies in automotive and aerospace applications. This not only enhances the overall product performance but also contributes to fuel efficiency and improved user experience. By investing in high-quality, customized solutions, manufacturers can ensure their products meet rigorous industry standards while delivering superior performance in the field.

This bar chart illustrates the critical importance of various factors related to custom cable assemblies in manufacturing success. Each reason is ranked on a scale of 1 to 10, highlighting their significance in enhancing product performance.

In today's fast-paced manufacturing environment, cable assemblies play a crucial role in streamlining processes and enhancing overall efficiency. These components serve as the backbone for electrical connectivity, ensuring that various machinery and equipment operate seamlessly. By facilitating reliable connections between different systems, cable assemblies help reduce downtime caused by connectivity issues, allowing manufacturers to maintain productivity levels and meet delivery deadlines.

Moreover, the integration of custom cable assemblies tailored to specific applications can significantly optimize workflow. Through effective organization and design, these assemblies minimize clutter and simplify installation procedures. This leads to quicker assembly times and reduces the likelihood of errors during the manufacturing process. Ultimately, investing in high-quality cable assemblies not only enhances operational efficiency but also contributes to a safer workplace by eliminating potential hazards caused by loose or improperly managed cables. The strategic use of cable assemblies is, therefore, essential for any manufacturer aiming for success in an increasingly competitive market.

In today's fast-paced manufacturing environment, the shift towards innovative alternatives to traditional cable assemblies is more crucial than ever. With the rising demand for streamlined production processes and efficient connectivity, manufacturers are increasingly turning to advanced cable assembly solutions that offer flexibility and reliability. Modern cable assemblies are designed to meet the needs of diverse applications, integrating robust materials and cutting-edge technology that enhance durability and performance.

Moreover, as businesses seek to minimize costs and maximize efficiency, innovative cable assembly options provide a competitive edge. These alternatives not only reduce dependency on expensive traditional systems but also facilitate easier installation and maintenance. As manufacturers embrace these modern solutions, they're not just keeping pace with industry trends; they're setting the stage for future growth and success in a rapidly evolving market. By leveraging advanced cable assemblies, companies can achieve higher productivity levels, ultimately leading to a stronger position in the marketplace.

| Reason | Description | Benefits | Modern Alternatives |

|---|---|---|---|

| Quality Assurance | High-quality assemblies reduce failures in manufacturing. | Enhanced reliability and reduced downtime. | Pre-terminated assemblies with rigorous testing. |

| Customization | Tailored assemblies to meet specific project needs. | Better fit and functionality for unique applications. | Configurable cable management solutions. |

| Cost Efficiency | Bulk production reduces costs per unit. | Lower overall expenses and improved margins. | Use of more affordable materials without compromising quality. |

| Improved Safety | Secure and reliable connections minimize hazards. | Enhanced workplace safety and compliance. | Use of insulated and resistant materials. |

| Scalability | Easily adjust production volumes as needed. | Flexibility to grow with business demands. | Automated production lines for rapid output. |

| Innovation | Integration of the latest technologies in assembly. | Staying competitive in the manufacturing landscape. | Smart cables with integrated sensors. |

| Time Savings | Streamlined assembly processes cut down production time. | Faster time to market and increased throughput. | Pre-assembled wiring harnesses ready for installation. |

Precision Cable Assemblies

16830 Pheasant Drive

Brookfield, WI 53005

Phone: 262-784-7887

Fax: 262-784-0681