In today's fast-paced technological landscape, optimizing your cable assembly design is crucial for enhancing overall efficiency and ensuring reliable performance in various applications. As the demand for high-quality cable assemblies grows, engineers and designers are constantly seeking innovative solutions to improve the functionality, durability, and manufacturability of their products. This blog will explore essential tips and strategies to help you streamline your cable assembly design process, reduce production costs, and minimize the risk of errors.

By focusing on factors such as material selection, layout considerations, and testing protocols, you can create a cable assembly design that not only meets industry standards but also exceeds customer expectations. Join us as we delve into the best practices that will empower you to refine your designs and achieve optimal results in your next project.

In today’s fast-paced industrial environment, efficient cable assembly design has become a critical factor in optimizing overall operational effectiveness. A recent report by the International Electrotechnical Commission highlights that over 30% of system failures in industrial applications can be attributed to poorly designed cable assemblies. By prioritizing design considerations such as strain relief, proper shielding, and robust insulation materials, industries can significantly reduce downtime and maintenance costs.

Furthermore, a study conducted by Research and Markets indicates that companies which implement optimized cable assembly designs can achieve up to a 25% reduction in production costs. This is achieved through enhanced manufacturing processes and minimized error rates. With the growing demand for high-performance electronics, understanding how to streamline cable assembly is essential. Companies leveraging advanced design principles not only improve product reliability but also enhance their competitive edge in the market.

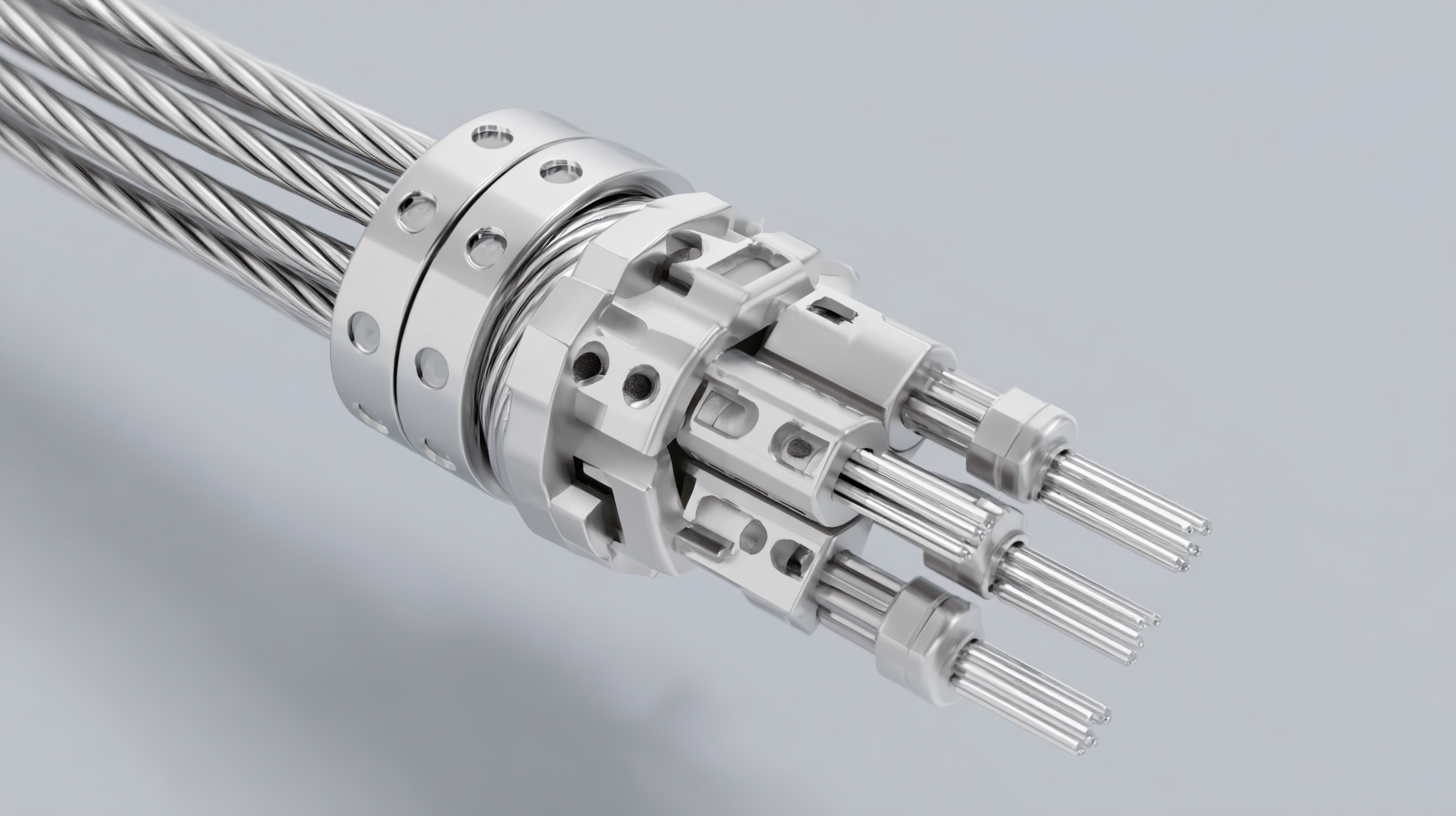

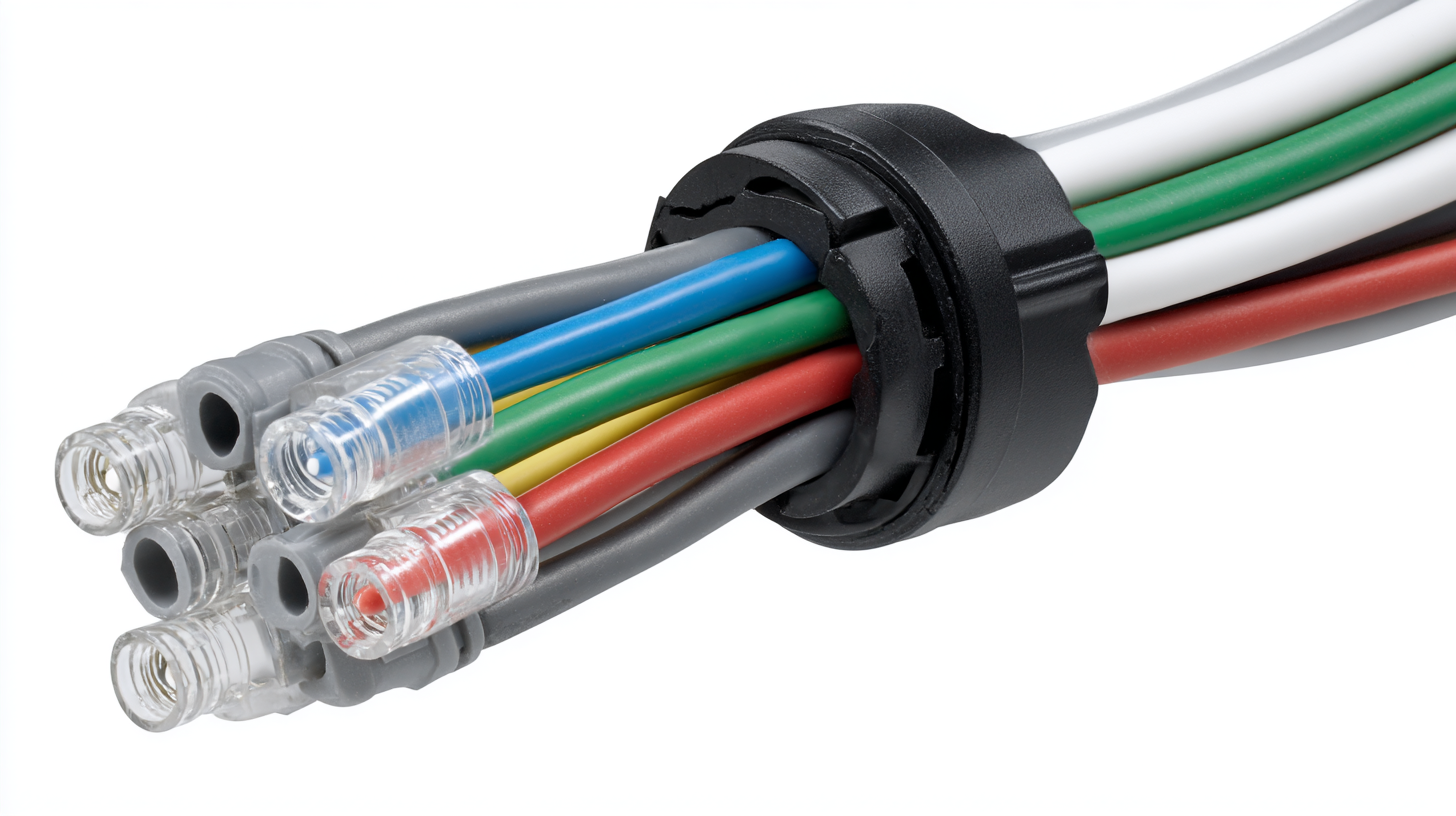

When it comes to optimizing cable assembly design, several key factors play a crucial role in ensuring both performance and longevity. First and foremost, selecting high-quality materials is imperative. The choice of insulation and conductor materials directly affects the assembly’s resistance to environmental factors, such as moisture and temperature fluctuations. For example, using thermoplastic elastomers can enhance flexibility and resistance to wear, while high-strand count conductors reduce electrical resistance, helping to achieve optimal signal integrity.

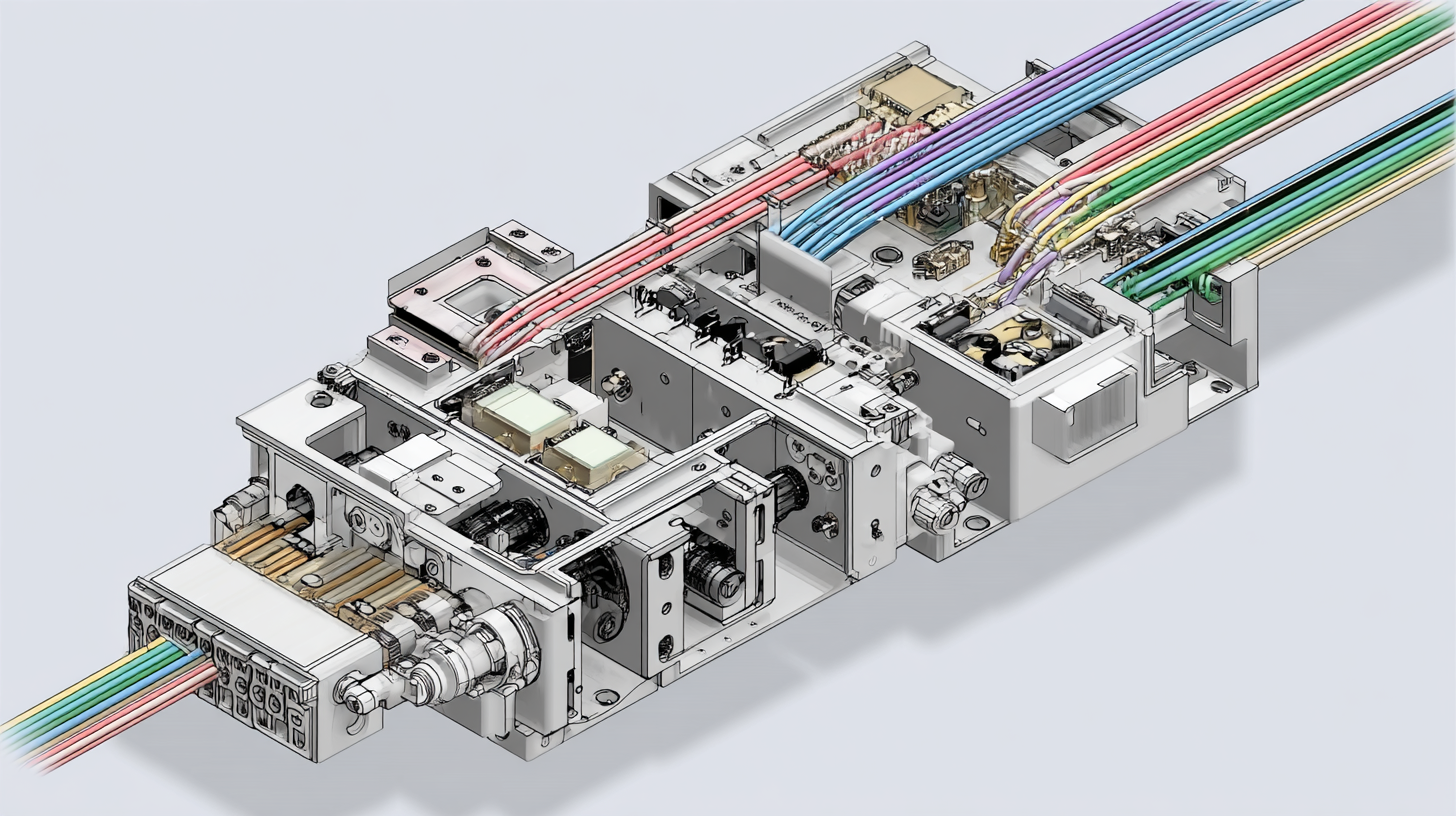

In addition to material selection, the design layout must be meticulously considered. Effective cable organization minimizes the risk of cross-talk and electromagnetic interference, which can degrade performance. Incorporating features like strain relief and proper routing can protect the assembly from mechanical stresses that may lead to premature failure. Furthermore, leveraging advanced manufacturing techniques, such as automated crimping and soldering, can enhance precision and reliability in the final product. By focusing on these aspects, designers can create cable assemblies that not only operate efficiently but also stand the test of time.

Advanced materials play a crucial role in optimizing cable assembly design, significantly enhancing efficiency and performance. By incorporating materials such as high-strength polymers, composites, and lightweight metals, manufacturers can reduce weight without sacrificing durability. For instance, utilizing thermoplastic elastomers can improve flexibility, allowing for tighter bends and easier installation, which is particularly beneficial in constrained spaces. Additionally, these advanced materials often exhibit superior thermal and chemical resistance, safeguarding the integrity of cable assemblies in demanding environments.

Advanced materials play a crucial role in optimizing cable assembly design, significantly enhancing efficiency and performance. By incorporating materials such as high-strength polymers, composites, and lightweight metals, manufacturers can reduce weight without sacrificing durability. For instance, utilizing thermoplastic elastomers can improve flexibility, allowing for tighter bends and easier installation, which is particularly beneficial in constrained spaces. Additionally, these advanced materials often exhibit superior thermal and chemical resistance, safeguarding the integrity of cable assemblies in demanding environments.

Furthermore, the implementation of innovative coatings and insulation materials can minimize signal loss and enhance conductivity. For example, using specialized fluoropolymer insulations not only provides excellent dielectric properties but also offers resistance to abrasion and moisture. This results in longer-lasting assemblies that maintain peak performance over time. By prioritizing advanced materials in the design phase, companies not only improve efficiency but also reduce overall production costs and maintenance needs, ultimately leading to more reliable cable systems in various applications.

In the competitive landscape of cable assembly production, implementing manufacturing best practices is essential for optimizing efficiency. According to a report by the IPC, lean manufacturing principles can reduce production waste by up to 30%, allowing companies to allocate resources more effectively and increase profit margins. Adopting methodologies such as Six Sigma and Just-In-Time (JIT) inventory management can streamline processes, leading to shorter lead times and improved product quality.

Moreover, a focus on automation can enhance productivity significantly. Data from the International Federation of Robotics highlights that automation in manufacturing has grown by over 50% in many sectors, contributing to a decrease in manual errors and an increase in assembly line speed. By investing in advanced technologies, companies can not only meet growing consumer demands but also maintain a competitive edge. Emphasizing continuous improvement and employee training will further nurture a culture of efficiency, ultimately driving down costs and boosting overall performance in cable assembly manufacturing.

| Aspect | Best Practice | Benefit | Impact on Efficiency |

|---|---|---|---|

| Material Selection | Use high-quality, lightweight materials | Reduces weight and increases durability | Improves handling and lowering shipping costs |

| Design for Manufacturability | Simplify designs to minimize components | Reduces assembly time and complexity | Increases production speed and reduces labor costs |

| Testing and Quality Control | Implement routine testing procedures | Ensures product reliability and performance | Minimizes returns and warranty claims |

| Supplier Collaboration | Establish long-term relationships with suppliers | Improves material availability and cost consistency | Streamlines production scheduling |

| Automation | Invest in automated assembly systems | Increases speed and reduces human error | Enhances overall production capacity |

When evaluating the effectiveness of cable assembly designs, industry metrics play a crucial role in determining operational success. Key performance indicators (KPIs) such as return on investment (ROI), defect rates, and lead times are essential for assessing the efficiency of cable assemblies. For instance, a recent survey by the Electronic Industry Alliance (EIA) found that companies that implement rigorous quality control measures can reduce defect rates by up to 30%. This reduction not only enhances product reliability but also minimizes costly rework, directly impacting the bottom line.

Moreover, lead time is another critical metric that deserves attention. According to a report from the Institute for Supply Management (ISM), businesses that streamline their cable assembly processes can achieve a lead time reduction of 20-40%. By optimizing supply chain logistics and leveraging automation technology, companies can significantly expedite production cycles, allowing for quicker responses to market demands. Such efficiencies not only enhance customer satisfaction but also enable businesses to capture greater market share in an increasingly competitive landscape.

Precision Cable Assemblies

16830 Pheasant Drive

Brookfield, WI 53005

Phone: 262-784-7887

Fax: 262-784-0681