In the fast-paced world of product development, effective prototype assembly plays a crucial role in turning innovative ideas into viable market solutions. According to a recent report by McKinsey & Company, organizations that optimize their prototype assembly processes are 2.5 times more likely to achieve successful product launches than those that do not. As competition intensifies, the ability to rapidly iterate prototypes while minimizing errors and costs becomes imperative. Companies leveraging agile methodologies in their prototype assembly stages can expedite feedback loops, facilitating valuable insights that drive design enhancements. Furthermore, a study by the Product Development Institute highlights that 70% of development teams cite inefficient assembly procedures as a significant roadblock in their product timelines. This underscores the necessity for established frameworks in prototype assembly to navigate common challenges effectively, ensuring that product developers can maintain speed without sacrificing quality in their journey to market.

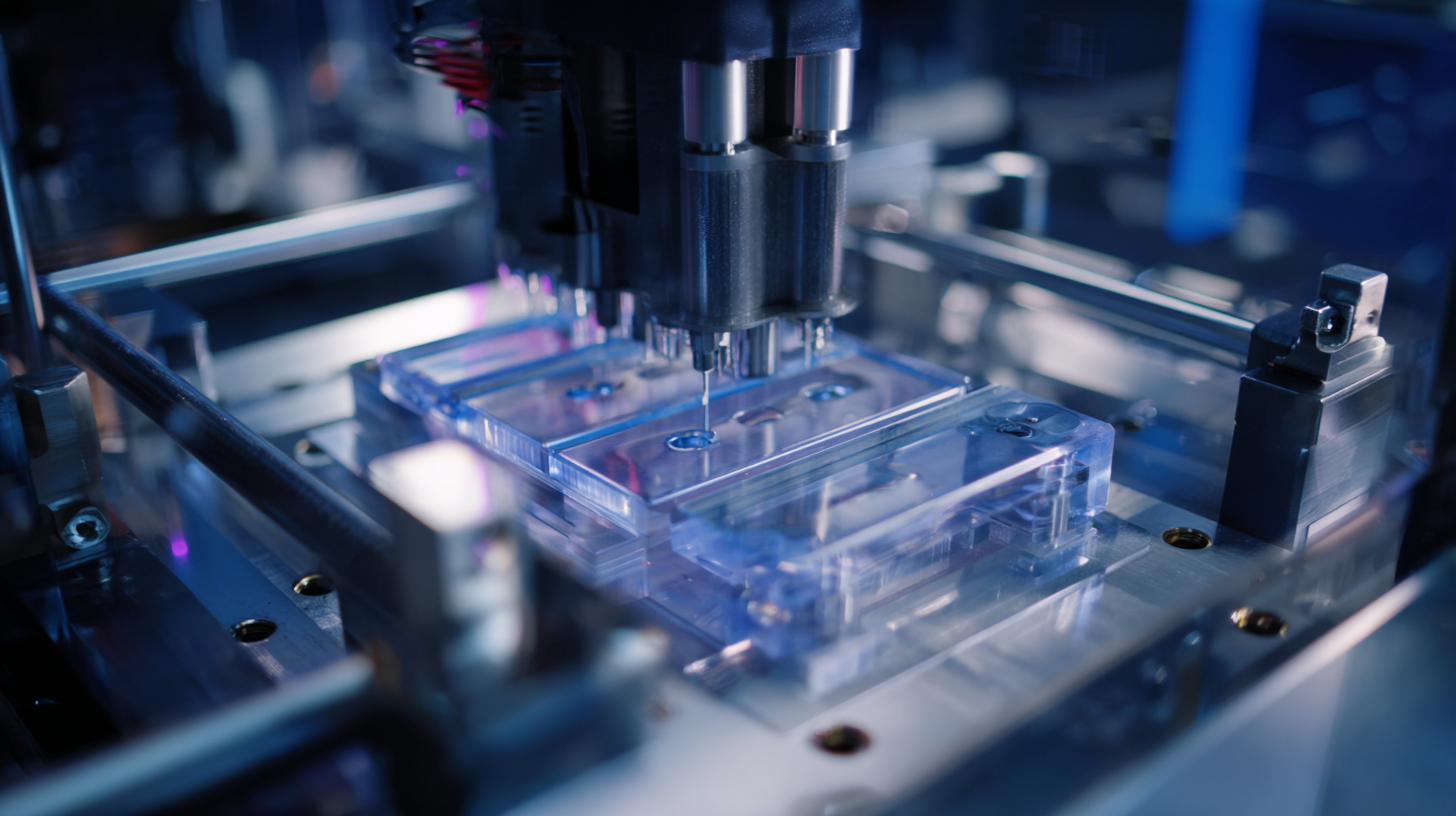

Prototype assembly plays a crucial role in the product development lifecycle. This phase allows designers and engineers to transition their ideas from concepts to tangible forms, enabling them to test functionality, aesthetics, and user experience. Through prototype assembly, teams can identify potential design flaws and performance issues early in the process, which is fundamental for minimizing costs and time delays in later stages of development.

Moreover, effective prototype assembly fosters collaboration among cross-functional teams, including engineering, manufacturing, and marketing. By bringing these diverse perspectives together, companies can ensure that prototypes meet both technical requirements and market expectations. This integration helps in refining the product based on feedback, ultimately leading to a more successful launch. In essence, investing in robust prototype assembly is vital for creating products that not only meet consumer needs but also stand out in competitive markets.

Prototype assembly is a critical phase in product development, yet it presents several common challenges that can hinder progress. According to a report by the Aberdeen Group, nearly 65% of product development teams encounter delays during prototype assembly, primarily due to design flaws and miscommunication among team members. These issues can lead to increased costs and extended timelines, emphasizing the need for a thorough understanding of the assembly process from the outset.

Another prevalent challenge is the integration of new technologies within prototypes. A study from the Product Development and Management Association (PDMA) found that companies that fail to adapt to technological advancements during the assembly phase see a 50% increase in time-to-market compared to those that do. This highlights the importance of staying current with tools and methods that can streamline assembly, such as advanced simulation software and automated assembly techniques. By proactively addressing these challenges, teams can ensure a more efficient prototype assembly process, ultimately paving the way for successful product development.

Effective communication among cross-functional teams is vital in overcoming the challenges of prototype assembly in product development. A recent report from the Project Management Institute (PMI) indicates that projects with clear communication strategies are 20% more likely to be completed on time and within budget. This underscores the significance of establishing a collaborative environment where diverse team members—from engineering to marketing—can voice their insights and concerns. Regular check-ins, shared digital platforms, and an established protocol for feedback can enhance transparency, ensuring everyone is on the same page throughout the prototype assembly process.

Moreover, the need for agile methodologies in product development further emphasizes the importance of communication. According to a survey conducted by McKinsey, organizations that implement agile practices report a 30% improvement in team collaboration and customer satisfaction. This adaptability allows teams to respond rapidly to feedback and modify prototypes effectively, ultimately leading to a more successful final product. Encouraging openness and fostering relationships across departments not only mitigates risks associated with miscommunication but also cultivates a culture of innovation that can drive product success in an increasingly competitive marketplace.

| Team Role | Communication Tools | Challenges Faced | Strategies for Improvement |

|---|---|---|---|

| Design | Slack, Miro | Misalignment on specifications | Regular alignment meetings |

| Engineering | Email, Jira | Delay in feedback | Set deadlines for responses |

| Product Management | Trello, Zoom | Lack of clarity in project goals | Create a shared project brief |

| Marketing | Google Meet, Asana | Insufficient understanding of product features | Conduct product demo sessions |

| Quality Assurance | Confluence, Teams | Inconsistent testing protocols | Develop a testing standard operating procedure |

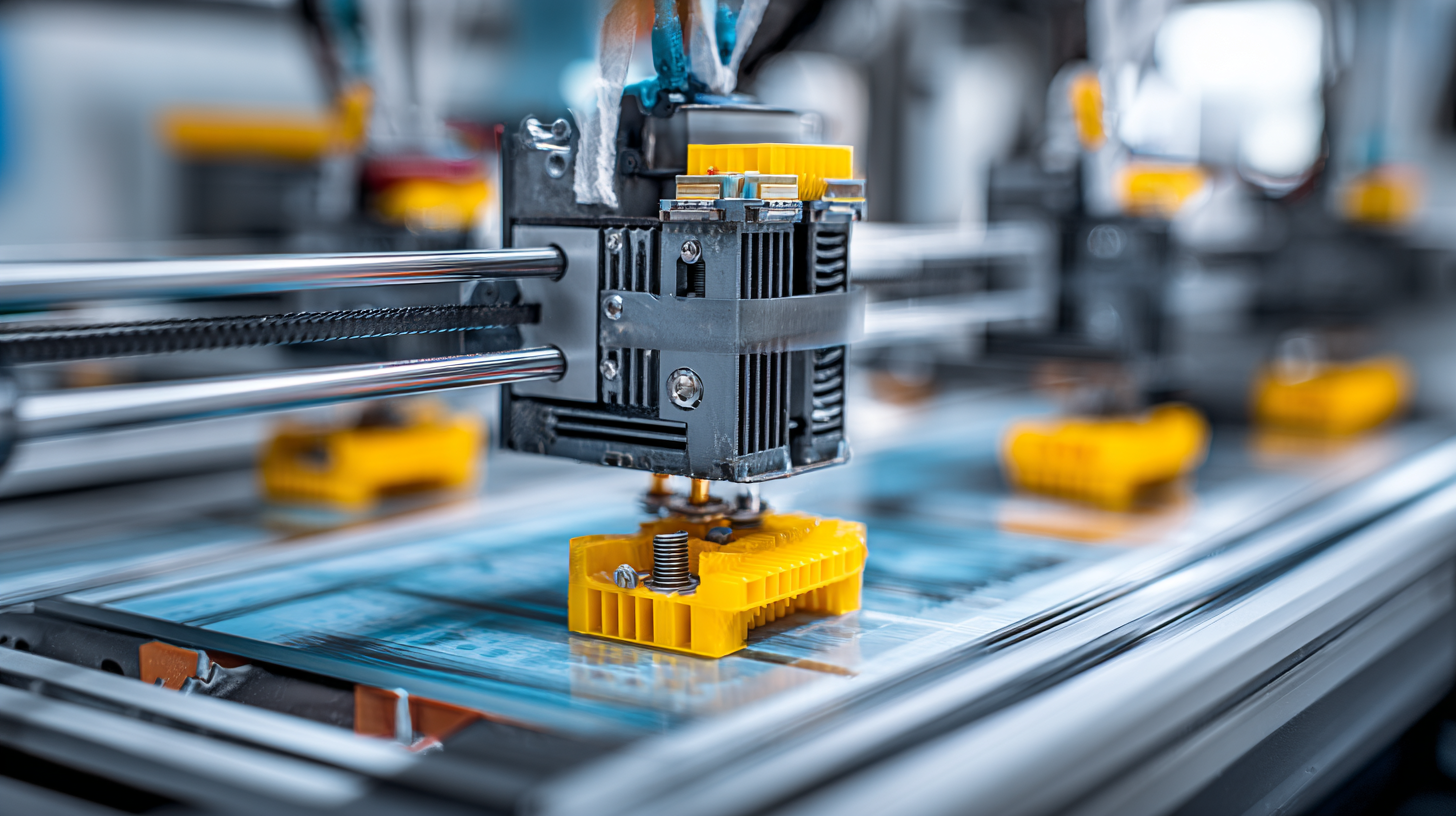

When it comes to navigating the challenges of prototype assembly, employing the right tools and techniques can make a significant difference. Advanced CAD software is essential for visualizing designs and ensuring accuracy during the assembly process. This technology allows engineers and designers to simulate various assembly scenarios, identifying potential issues before physical prototypes are built. Additionally, utilizing 3D printing can accelerate the creation of components, enabling rapid iterations and adjustments based on real-world feedback, thus reducing wasted materials and time.

Another key technique for streamlining prototype assembly is the implementation of modular design principles. By designing components that can be easily categorized and swapped, teams can simplify assembly processes and enhance flexibility. Organizing workspaces and employing digital project management tools also contributes to efficient workflows. These tools promote better communication among team members and facilitate tracking of progress and challenges, ensuring that everyone is aligned and informed throughout the prototype assembly phase. Such strategies not only reduce the time and costs associated with product development but also increase the likelihood of designing a successful product that meets market demands.

Effective testing and iteration on prototypes are crucial steps in product development that can significantly reduce time to market and enhance product quality. According to a report by McKinsey, companies that efficiently test and iterate on their prototypes can cut development time by up to 30%. This efficiency not only speeds up the design process but also allows teams to identify and resolve potential issues early, reducing costly redesigns later in the development cycle.

To navigate the challenges of prototype assembly, it is essential to adopt best practices such as rapid prototyping and user-centered testing. Utilizing tools like 3D printing can facilitate quick changes and improvements based on user feedback. A survey conducted by the Product Development and Management Association (PDMA) found that organizations implementing rapid prototyping techniques reported a 40% increase in customer satisfaction due to enhanced responsiveness to market needs. Engaging directly with users during the testing phase enables teams to gather valuable insights, ensuring that subsequent iterations are more aligned with user expectations and market demands.

Precision Cable Assemblies

16830 Pheasant Drive

Brookfield, WI 53005

Phone: 262-784-7887

Fax: 262-784-0681