As we approach the 2025 China Import and Export Fair, the spotlight increasingly shines on the realm of cable assembly design, where innovation drives connectivity and efficiency across industries. The emergence of novel design trends in this sector promises to revolutionize how we approach applications ranging from telecommunications to automotive engineering. Exhibitors and attendees alike will be keen to explore cutting-edge technologies that enhance performance while meeting the growing demand for sustainability. From advancements in materials to smarter assembly techniques, the discussions at the fair will serve as a testament to the vital role of cable assembly design in shaping the future of global trade. This event not only showcases the latest innovations but also provides a platform for networking and collaboration among industry leaders, making it an unmissable occasion for anyone involved in the cable assembly landscape.

The 2025 Canton Fair promises to showcase groundbreaking trends in cable assembly design, significantly influenced by the application of innovative materials. As industries continue to demand higher performance and efficiency, manufacturers are increasingly exploring advanced materials such as lightweight composites, thermoplastic elastomers, and bio-based substances. These materials not only enhance durability and flexibility, but also contribute to sustainability, appealing to eco-conscious consumers and businesses alike.

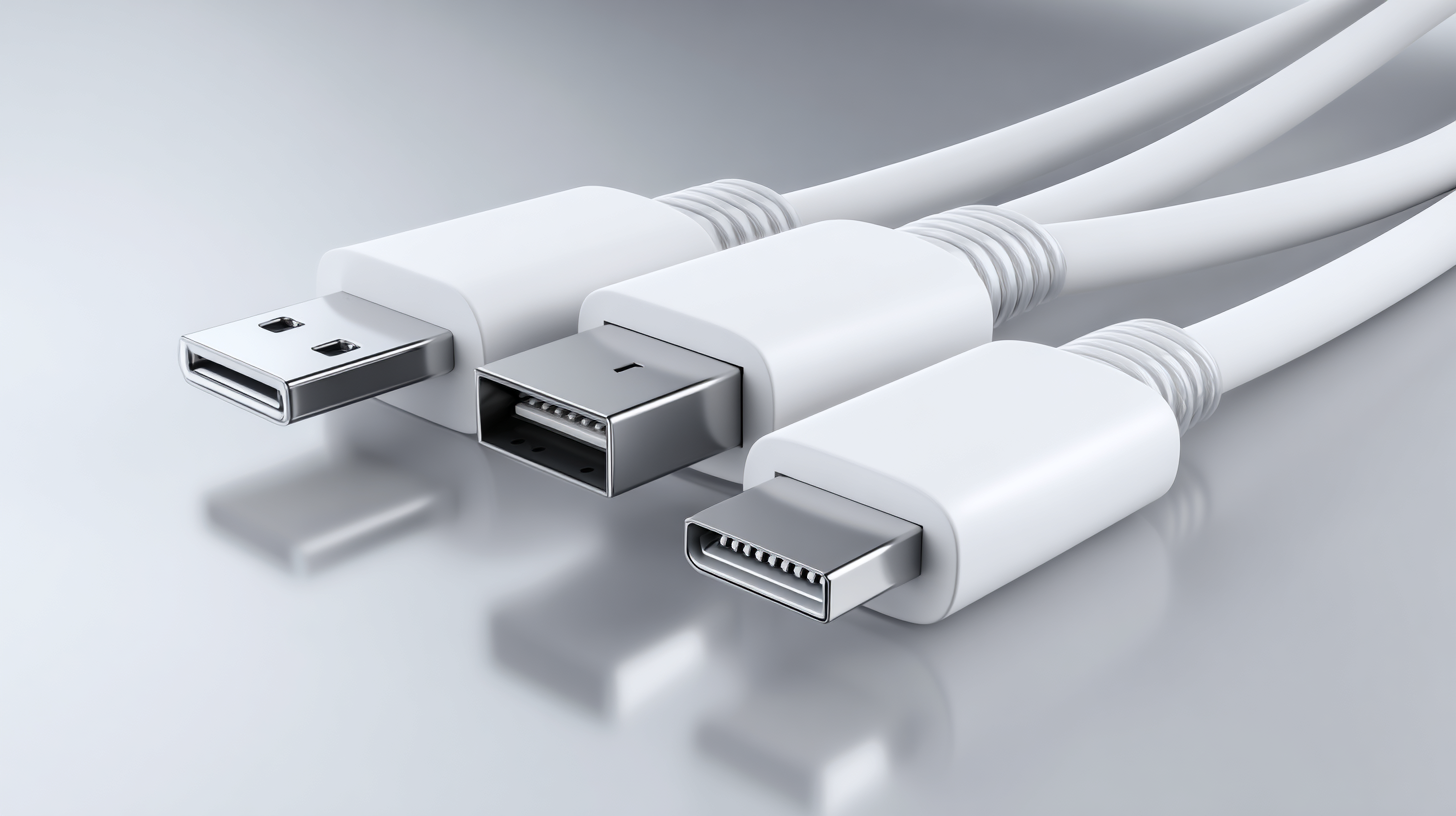

One of the standout innovations likely to be highlighted at the fair is the integration of smart materials that can respond dynamically to environmental changes. For example, shape-memory alloys and conductive polymers may play roles in creating cable assemblies that can adapt to varying temperatures and stresses, thereby extending the lifespan of electronic devices. Additionally, advances in nanotechnology are paving the way for thinner, yet stronger cables, which can facilitate more compact designs in today's fast-evolving tech landscape. With these monumental shifts, the 2025 Canton Fair will be a pivotal event for stakeholders in the cable assembly industry, showcasing how innovative materials are steering the future of design.

The landscape of cable assembly design is being reshaped by several emerging technologies which are enhancing efficiency in the industry. As we look towards the 2025 China Import and Export Fair, it's essential to highlight how advancements such as artificial intelligence (AI), automation, and advanced materials are revolutionizing the production and performance of cable assemblies. AI-driven analytics are streamlining design processes, allowing for predictive modeling that results in more efficient layouts and reduced material waste.

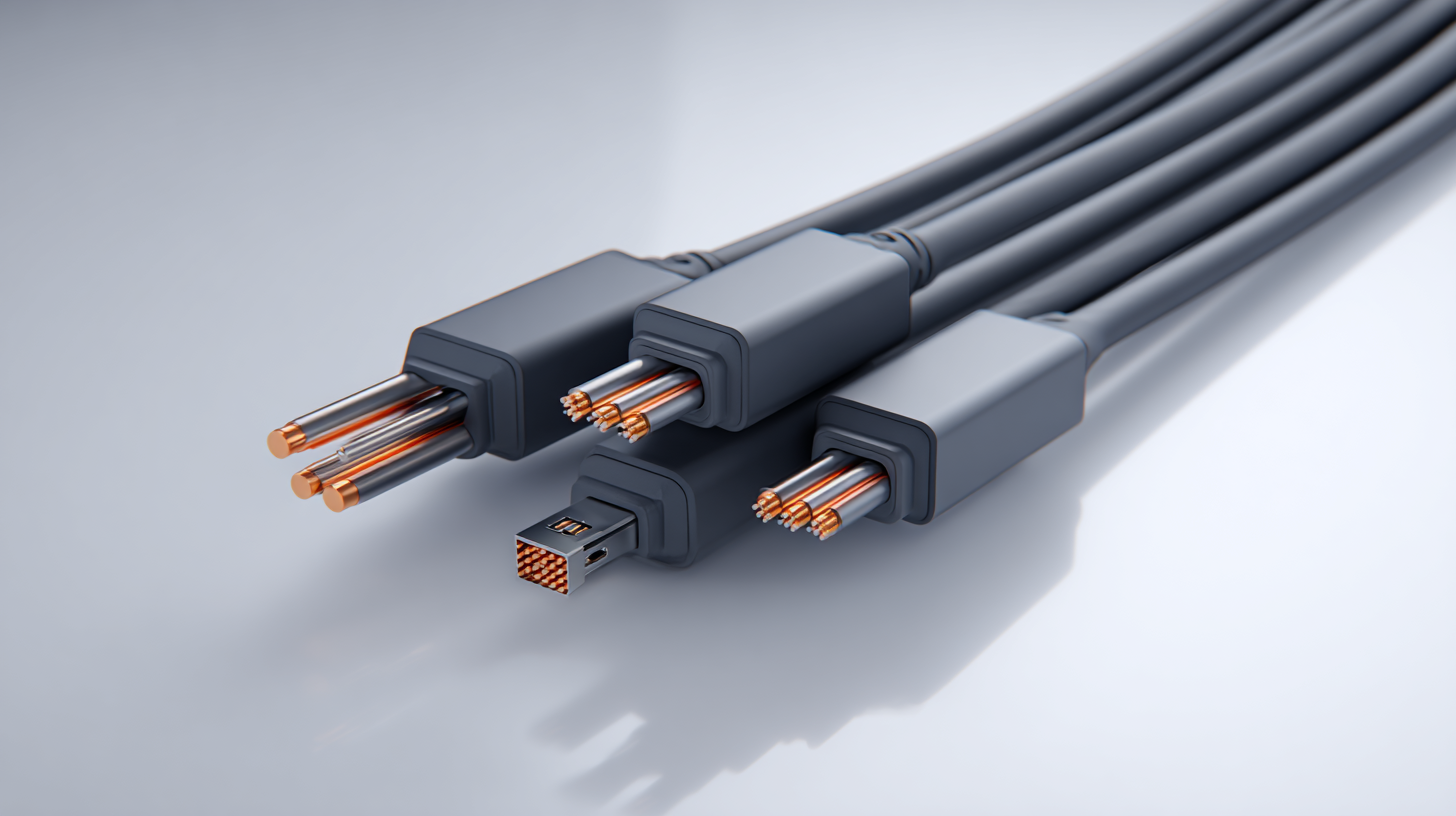

Moreover, automation technologies are redefining manufacturing workflows, enabling higher precision and faster production cycles. Robotics and automated assembly lines are not only reducing labor costs but also increasing consistency in product quality. Coupled with the use of advanced materials, such as lightweight composites and heat-resistant polymers, manufacturers can produce cable assemblies that are not only efficient but also more durable and adaptable to various applications.

These trends signify a transformative shift in the industry, setting the stage for enhanced efficiency and performance by 2025.

As the world increasingly shifts towards sustainable practices, cable assembly manufacturers are adapting their approaches to meet growing environmental consciousness. Recent reports suggest that the global market for sustainable cable assemblies is expected to grow at a compound annual growth rate (CAGR) of 7% through 2027. This trend underscores a collective effort within the industry to align with circular economy principles, emphasizing resource efficiency and reduced waste in cable production.

A significant facet of this sustainability movement is the adoption of eco-friendly materials. Analysts project that by 2025, more than 30% of cable assemblies will be made using recyclable or biodegradable materials, a marked increase from previous years. This shift not only enhances the product's life cycle management but also appeals to manufacturers aiming to meet stringent environmental regulations. Embracing technologies that facilitate energy-efficient manufacturing processes further supports these sustainability goals, reducing the carbon footprint associated with cable assembly production. As we approach the 2025 China Import and Export Fair, it is clear that innovation in sustainable practices will shape the future of the cable assembly industry.

As industries evolve, the demand for customized cable assemblies is on the rise, particularly highlighted by the anticipated growth in the global coastal power market, which is projected to reach $1.99 billion in 2025 and expand to $3.69 billion by 2032. This significant increase reflects the industry's shift towards tailored solutions, responding to diverse applications in sectors such as renewable energy and telecommunications.

Additionally, the thermoplastic polyurethane (TPU) market is set to experience robust growth, with projections indicating an increase from $2.14 billion in 2024 to $2.93 billion by 2032, reflecting a compound annual growth rate of 4.04%. This growth underscores the versatility of TPU in cable assembly designs, allowing for customized solutions that cater to specific industrial requirements and enhance performance in challenging environments. As technology continues to advance, manufacturers are focusing on leveraging these materials to develop highly specialized cable assemblies that meet the unique demands of various industries.

The landscape of cable assembly design is poised for transformative changes, driven by advancements in manufacturing techniques that prioritize efficiency and customization. As industries increasingly adopt additive manufacturing, companies are witnessing improvements in production agility and lead times. For instance, manufacturers are leveraging these innovations to create low-loss flexible cable assemblies that meet stringent performance requirements while streamlining their supply chains. A recent report indicated that the global market for cable assemblies is expected to reach $260 billion by 2027, underscoring the growing demand for high-performance wiring solutions across sectors from automotive to aerospace.

Additionally, the integration of advanced materials such as ground-breaking polymers is redefining industry standards. These materials not only enhance the durability and performance of cable assemblies but also support the trend towards miniaturization in electronics. The emphasis on multi-material additive manufacturing signifies a move away from traditional methods, enabling more complex designs that were previously unachievable. This shift aligns with a broader industry push towards sustainable practices and cost-effectiveness, with a significant percentage of manufacturers aiming to incorporate such innovative techniques into their production cycles by 2025.

| Trend | Description | Application | Expected Impact |

|---|---|---|---|

| Modular Design | Flexible cable assemblies that allow for easy modification and upgrades. | Consumer Electronics, Automotive | Increased product lifespan and reduced costs. |

| Eco-Friendly Materials | Use of sustainable and recyclable materials in cable assembly production. | Telecommunications, Industrial Applications | Lower environmental impact and compliance with regulations. |

| Advanced Coating Technologies | Innovative coatings that enhance durability and resistance to environmental factors. | Aerospace, Medical Devices | Improved reliability and lifespan of components. |

| Smart Cables | Integration of sensors and functionalities into cable assemblies for monitoring. | IoT Devices, Smart Homes | Enhanced functionality and data insight capabilities. |

| Automation in Manufacturing | Use of robotics and automated processes in cable assembly line. | All industrial sectors | Efficiency gains and error reduction in production. |

Precision Cable Assemblies

16830 Pheasant Drive

Brookfield, WI 53005

Phone: 262-784-7887

Fax: 262-784-0681