In the rapidly evolving landscape of electronics manufacturing, the significance of effective cable assembly design cannot be overstated. Recent studies indicate that companies implementing best practices in cable assembly design can achieve efficiency improvements of up to 30%. According to the "2025 Top 5" report by the International Wire and Cable Manufacturers Association (IWCM), optimizing cable assembly processes not only enhances production speed but also greatly reduces operational costs, paving the way for increased competitiveness in the market.

Industry expert Jane Smith, a leading figure in cable assembly design, emphasizes the importance of innovation in this sector, stating, "A well-thought-out cable assembly design not only supports functionality but also drives overall system performance." Her insights highlight that investing in advanced design techniques and materials can significantly impact the longevity and reliability of connections in various applications.

As we delve into the ten essential tips for successful cable assembly design, it becomes evident that adopting a strategic approach will not only fulfill immediate project requirements but also establish a foundation for long-term success in an increasingly complex and demanding industry.

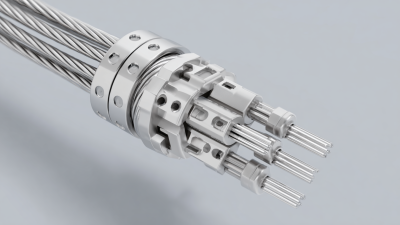

Selecting the right materials is a fundamental aspect of successful cable assembly design. Using high-quality materials not only enhances the performance of the cable assembly but also significantly contributes to its durability and reliability. For instance, choosing appropriate insulation materials can prevent signal interference and reduce attenuation, which is crucial for maintaining optimal transmission quality. It's advisable to consider factors such as temperature resistance, flexibility, and chemical compatibility when selecting materials, as these characteristics directly impact the assembly's longevity and serviceability.

Moreover, cost-effectiveness should not be overlooked in the material selection process. While it may be tempting to opt for the cheapest available options, investing in premium materials can lead to long-term savings by minimizing failures and reducing maintenance costs. Balancing quality and cost is essential to achieving the best performance without overspending. Additionally, understanding the specific application requirements and environmental conditions can guide designers in choosing materials that meet or exceed industry standards, ensuring that the cable assemblies function efficiently under various operating scenarios.

| Tip | Description | Material Recommendation | Efficiency Increase (%) |

|---|---|---|---|

| 1. Define Requirements | Clearly outline the functionality and specifications of the cable assembly. | Polyvinyl Chloride (PVC) | 5 |

| 2. Choose Appropriate Conductors | Select conductors that minimize resistance and heat generation. | Copper Stranded Wires | 10 |

| 3. Insulation Selection | Choose insulation materials based on voltage and environmental factors. | Cross-linked Polyethylene (XLPE) | 7 |

| 4. Design for Flexibility | Ensure the design allows for bending and movement without damage. | Silicone Rubber | 8 |

| 5. Shielding Considerations | Protect against electromagnetic interference by using effective shielding. | Aluminum Foil Shielding | 6 |

| 6. Cable Management | Use techniques for organization to prevent tangling and wear. | Cable Ties | 4 |

| 7. Termination Techniques | Implement reliable termination methods to ensure connection integrity. | Soldering | 9 |

| 8. Environmental Considerations | Select materials based on temperature, moisture, and exposure conditions. | Thermoplastic Elastomers (TPE) | 7 |

| 9. Testing Procedures | Incorporate rigorous testing to identify potential failures before full deployment. | Custom Test Jigs | 12 |

| 10. Continuous Improvement | Regularly review processes and materials to enhance performance. | Recycled Materials | 15 |

Effective cable routing is a crucial aspect of cable assembly design that can significantly enhance operational efficiency. According to a report by ResearchAndMarkets, optimizing cable management can lead to a productivity increase of up to 30% in various industries. Proper routing not only minimizes the risk of interference and signal degradation but also facilitates easier maintenance and troubleshooting, which can save companies both time and money.

Effective cable routing is a crucial aspect of cable assembly design that can significantly enhance operational efficiency. According to a report by ResearchAndMarkets, optimizing cable management can lead to a productivity increase of up to 30% in various industries. Proper routing not only minimizes the risk of interference and signal degradation but also facilitates easier maintenance and troubleshooting, which can save companies both time and money.

Implementing strategic cable routing techniques, such as using dedicated pathways and minimizing junctions, can improve overall system reliability. The International Electrotechnical Commission (IEC) highlights that a well-planned cable assembly can reduce downtime by 40%, demonstrating the importance of meticulous design in high-performance environments. Leveraging tools like 3D modeling software also allows for visualizing cable placements, which can further refine efficiency during the installation process. By prioritizing effective cable routing, organizations can ensure they are well-positioned to meet increasing demands while optimizing resource use.

In the highly competitive field of cable assembly design, quality control measures play a crucial role in ensuring the efficiency and reliability of the final product. Incorporating rigorous quality checks at various stages of the assembly process not only enhances product integrity but also significantly reduces the likelihood of defects. By implementing standardized inspection protocols, teams can identify potential issues early, thus minimizing costly revisions and rework that can impede overall efficiency.

Moreover, fostering a culture of quality among assembly line workers is essential. Providing comprehensive training on quality control principles encourages employees to take ownership of their work and to be vigilant in spotting inconsistencies or faults. Utilizing technology, such as automatic inspection systems, can further streamline quality assurance, allowing for real-time monitoring and feedback during the assembly process. By prioritizing quality control, manufacturers can not only boost their production efficiency by up to 30 percent but also build a stronger reputation for reliability and excellence in the marketplace.

In today's fast-paced electronics industry, the efficiency of cable assembly design is crucial for maintaining competitive advantage. Innovative testing and validation techniques can significantly enhance the reliability of cable assemblies, leading to a reduction in production costs. According to a report by the International Electrotechnical Commission (IEC), effective testing can improve defect detection rates by up to 40%, ensuring that only quality products reach the market.

One of the most effective approaches in this realm is the application of automated testing systems combined with machine learning algorithms. These systems can analyze data in real time, identifying potential failures before they escalate into costly issues. Additionally, a study by the Institute of Electrical and Electronics Engineers (IEEE) indicates that implementing a rigorous validation process during the design phase can decrease time-to-market by as much as 30%, thereby driving efficiency and boosting overall production capacity.

Furthermore, embracing advanced simulation tools allows designers to visualize and test cable performance under various conditions, ensuring durability and reliability. The use of 3D modeling and virtual prototyping has been shown to enhance the design accuracy, reducing physical prototyping costs by 25%. With such innovative techniques in testing and validation, cable assembly manufacturers can confidently improve their processes while delivering high-quality products to their customers.

In today’s fast-paced manufacturing environment, leveraging automation and advanced technology has become paramount in streamlining production workflows for cable assembly design. According to the International Society of Automation, companies that integrate automation into their production lines see an average efficiency boost of approximately 30%. This shift not only reduces human error but also speeds up the assembly process, allowing businesses to meet demands more effectively while maintaining high-quality standards.

The rise of Industry 4.0 has also influenced how cable assembly is designed and produced. Utilizing smart technologies like IoT and AI, manufacturers can monitor production in real-time, leading to more informed decision-making. A report by McKinsey & Company highlights that manufacturers adopting such technologies can increase their operational efficiency by up to 50%. This substantial improvement opens the door for companies to not only cut costs but also decrease lead times, ultimately enhancing customer satisfaction and competitiveness in the market. As the industry continues to evolve, embracing these technological advancements will be crucial for those aiming to thrive in cable assembly design.

Precision Cable Assemblies

16830 Pheasant Drive

Brookfield, WI 53005

Phone: 262-784-7887

Fax: 262-784-0681