When embarking on a project that requires wiring solutions, the selection of the right assembly wire plays a pivotal role in ensuring both functionality and safety. Assembly wires come in various types, each designed to cater to specific needs and applications, making it crucial to understand their unique characteristics before making a decision.

Factors such as wire gauge, insulation type, temperature rating, and flexibility can significantly impact the performance and longevity of your project. By delving into the essentials of choosing assembly wire effectively, this guide aims to equip engineers, designers, and hobbyists with the knowledge needed to select the most suitable wire type, ultimately leading to enhanced project outcomes and reduced risk of failure.

Whether you are working on electronics, automotive applications, or general wiring tasks, making informed choices will ensure that your assembly wire meets the demands of your specific project requirements.

When selecting assembly wire for your project, it's crucial to understand

the different types available. Assembly wires come in various forms, including stranded,

solid, and specialty wires, each with unique properties suited for

distinct applications.

Stranded wire, made of multiple small strands twisted together, is highly flexible and ideal for dynamic applications where movement is constant.

In contrast, solid wire, composed of a single, thicker conductor, offers better conductivity for static applications

but is less flexible. According to industry reports, stranded wire is generally preferred for automotive applications, owing to its durability

and resistance to fatigue.

Stranded wire, made of multiple small strands twisted together, is highly flexible and ideal for dynamic applications where movement is constant.

In contrast, solid wire, composed of a single, thicker conductor, offers better conductivity for static applications

but is less flexible. According to industry reports, stranded wire is generally preferred for automotive applications, owing to its durability

and resistance to fatigue.

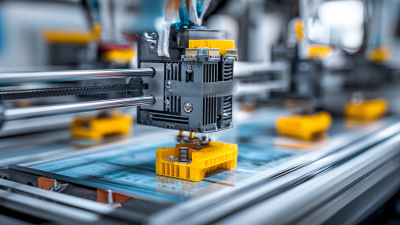

Additionally, the recent advancements in wire harness assembly have highlighted the importance of innovation

in this sector. A collaboration between students and a major automotive manufacturer is working to automate wiring harness processes, traditionally viewed as time-consuming

and labor-intensive. Reports indicate that automation can significantly reduce production time by up to 30%,

leading to both efficiency and cost savings. As projects scale in complexity, staying informed

about the latest wire technologies and their applications will ensure that you choose the right assembly wire, facilitating smoother operations

and enhanced performance in your designs.

When selecting assembly wire for your project, there are several key factors to consider that will significantly impact the performance and durability of your final product. First, it is essential to evaluate the wire's material. Common options include copper, aluminum, and special alloy wires. Copper, known for its excellent electrical conductivity, is often preferred for high-performance applications, while aluminum is lighter and more cost-effective for budget-sensitive projects. Additionally, the wire's gauge plays a critical role, as it determines the thickness and current-carrying capacity. Choosing the appropriate gauge ensures safe and efficient operation in your specific application.

Another important consideration is the insulation type. Various insulating materials, such as PVC, polyurethane, and silicone, offer different benefits in terms of temperature resistance, flexibility, and chemical resistance. For projects exposed to harsh environments, selecting wires with high-quality insulation that can withstand extreme temperatures and chemicals is vital. Furthermore, the wire’s flexibility and bend radius should also be assessed, particularly in applications requiring intricate routing or movement. By carefully evaluating these factors, you can select the most suitable assembly wire that meets your project’s requirements for reliability and functionality.

When selecting assembly wire for your project, understanding the various materials available is crucial. Copper wire stands as a popular choice due to its excellent conductivity and flexibility, which allow for efficient energy transfer and ease of handling. However, it can be prone to corrosion and is relatively heavy compared to other materials, which may not be ideal for all applications.

When selecting assembly wire for your project, understanding the various materials available is crucial. Copper wire stands as a popular choice due to its excellent conductivity and flexibility, which allow for efficient energy transfer and ease of handling. However, it can be prone to corrosion and is relatively heavy compared to other materials, which may not be ideal for all applications.

Aluminum wire, on the other hand, offers a lightweight alternative, making it suitable for overhead transmission lines. While aluminum has lower conductivity than copper, its cost-effectiveness and resistance to corrosion make it a viable option for many projects.

Another material worth considering is stainless steel wire, which is known for its strength and durability. It is particularly beneficial in harsh environments where resistance to rust and wear is essential. The downside, however, is that stainless steel can be more challenging to work with due to its rigidity and higher cost. Lastly, there are specialty wires such as tinned copper, which combine the advantages of copper with added protection against corrosion, making them an excellent choice for marine applications. In summary, each material presents distinct advantages and disadvantages that can significantly impact the success of your project, making careful consideration essential.

Choosing the right assembly wire for your project is crucial to ensure safety,

efficiency, and durability.

When selecting assembly wire, consider the specific requirements of your electrical system. The wire's gauge, insulation type,

and voltage rating should align with your project's needs. A common mistake is to overlook the wire's temperature rating,

which can lead to insulation failure and potential hazards.

Tips: Always check the manufacturer's specifications and recommendations

for compatibility with your components. Additionally, consider the environment in which the wire will be used. For outdoor applications,

using UV-resistant and waterproof insulation is essential to prolong the wire's lifespan.

Another key aspect to consider is the wire's flexibility and ease of handling. For projects that require intricate routing,

opting for a flexible stranded wire instead of a solid wire can make your assembly process much more manageable. Finally,

don't forget to assess the cost versus quality; investing in high-quality wire

can save you from costly repairs and replacements down the line.

Assembly wire plays a crucial role across various industries, ranging from automotive and aerospace to electronics and telecommunications. In the automotive sector, for instance, the global demand for assembly wire is projected to grow significantly, primarily driven by the increasing need for lightweight and durable materials. According to a recent market report, the global assembly wire market is expected to reach USD 1.2 billion by 2024, emphasizing its importance in vehicle manufacturing. The aerospace industry also heavily relies on assembly wire for harnessing applications, ensuring safety and performance in high-stress environments.

Tips: When selecting assembly wire for a specific project, consider the operating temperature and environmental conditions. For high-temperature applications, materials such as silicon-coated or PTFE-insulated wires may be beneficial.

In the electronics field, assembly wire is vital for ensuring reliable connections in various devices. The increasing miniaturization of components has led to a surge in demand for fine-gauge wires that can accommodate tight spaces without sacrificing performance. A study by the Electronics Industry Association indicates that assembly wire consumption could increase by 15% in the next five years as the demand for consumer electronics surges.

Tips: Always evaluate the wire's gauge and insulation type to ensure compatibility with the intended application and to maximize longevity and efficiency.

Precision Cable Assemblies

16830 Pheasant Drive

Brookfield, WI 53005

Phone: 262-784-7887

Fax: 262-784-0681