In the ever-evolving field of electronics, the importance of effective cable assembly design cannot be overstated. A well-executed design not only enhances the overall performance of a system but also significantly contributes to its long-term reliability. As the backbone of many electronic applications, cable assemblies play a crucial role in facilitating seamless communication and power distribution between components. Therefore, the challenge lies in creating designs that are not only functional but also optimized for specific operational environments.

To achieve optimal performance and reliability, engineers and designers must consider various factors that influence cable assembly design. These include material selection, connector types, and insulation properties, all of which can impact the efficiency and durability of the assembly. Additionally, awareness of environmental conditions—such as temperature fluctuations and exposure to chemicals—can guide the design process to ensure that assemblies remain robust under challenging circumstances. By focusing on these key elements, professionals can develop cable assemblies that meet rigorous industry standards while promoting longevity and minimizing maintenance needs.

Cable assembly design plays a pivotal role in ensuring optimal performance and reliability in various industries, from telecommunications to automotive engineering. Key principles such as material selection, mechanical stability, and efficient routing significantly affect electrical performance. For instance, the latest studies highlight that using advanced materials can improve the durability and longevity of cable assemblies. As showcased in recent innovations, integrating internal cabling into vehicles allows for streamlined designs that do not compromise overall weight, enhancing performance without sacrificing reliability.

Moreover, the application of principles from modular designs, such as those seen in deployable mechanisms and antenna systems, illustrates the growing trend of versatility and efficiency in cable assembly. By utilizing geometrical configurations, like the tetrahedral symmetrical combination unit, manufacturers can enhance the functionality of their products while ensuring they remain lightweight and adaptable. This is particularly relevant when considering the increasing demands for high-performance and lightweight components in the aerospace and defense sectors, where the reliability of cable assemblies is critical for overall system integrity. Hence, embracing effective cable assembly design principles is not only essential for technical success but also for meeting evolving industry standards.

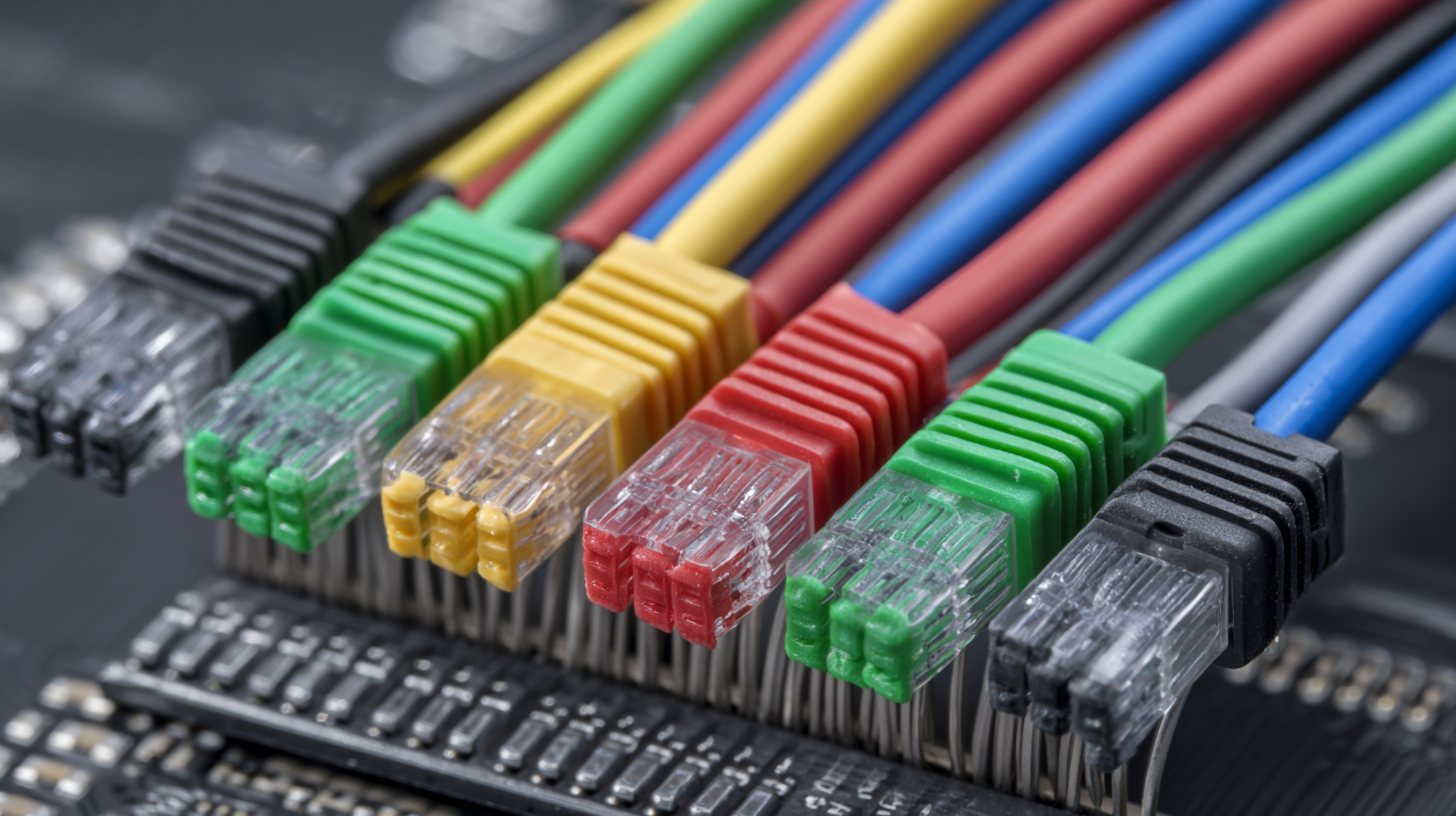

When designing cable assemblies, the selection of materials plays a crucial role in ensuring optimal performance and long-term reliability. Key materials such as copper, aluminum, and various types of insulation each contribute distinct properties that can influence the operational lifespan and efficiency of the cable assembly in different environments. Understanding these materials' strengths and weaknesses is essential for achieving the desired reliability in applications ranging from utility infrastructures to satellite communications.

**Tips:**

- **Choose High-Quality Conductors:** Opt for materials with excellent conductivity, like copper, to minimize energy loss and enhance performance.

- **Consider Environmental Conditions:** Select insulation materials that can withstand the specific conditions they will face, such as temperature extremes, moisture, and chemical exposure.

- **Stay Informed on Market Trends:** As the cable assembly market expands, focusing on innovative materials and technologies will keep you ahead in delivering reliable and efficient solutions.

Investing time in material selection not only improves the performance of cable assemblies but also boosts their reliability, thus aligning with the industry's projected growth and evolving standards. As the market continues to grow, with a significant CAGR anticipated, understanding these key materials becomes increasingly important for developers and manufacturers in minimizing failure rates and enhancing service life.

| Material Type | Conductivity (S/m) | Temperature Resistance (°C) | Flexibility Rating | Durability (Cycles) |

|---|---|---|---|---|

| Copper | 5.8 x 10^7 | 200 | High | 1,000,000 |

| Aluminum | 3.5 x 10^7 | 150 | Medium | 500,000 |

| Teflon (PTFE) | N/A | 260 | Very High | 1,000,000 |

| PVC (Polyvinyl Chloride) | N/A | 70 | Low | 100,000 |

| Silicone | N/A | 180 | High | 1,000,000 |

When designing cable assemblies, ensuring signal integrity is paramount for optimal performance and reliability. One fundamental technique is to maintain proper impedance throughout the cable assembly. This involves selecting connectors, cables, and adapters that all have matched impedance to minimize reflections and loss of signal quality. Additionally, careful consideration of the cable lengths and routing can prevent unwanted interference and maintain signal stability.

Another critical aspect of ensuring signal integrity is the use of effective shielding techniques. By employing braided or foil shielding within the cable assembly, external electromagnetic interference can be significantly reduced. Furthermore, twisting pairs of wires in a cable can help cancel out noise and enhance differential signaling. Implementing high-quality materials for insulation and jackets also mitigates signal degradation, contributing to more reliable performance in various environments. By focusing on these techniques, designers can create cable assemblies that excel in transmitting signals without compromising performance.

When designing cable assemblies, particularly for environments that demand high reliability such as medical or automotive applications, it is crucial to consider various environmental factors. Environmental influences like humidity, temperature fluctuations, and exposure to chemicals can significantly impact the performance and longevity of cable assemblies. Recent trends indicate that the demand for connectors in mobile medical equipment is increasing, requiring solutions that balance both portability and connectivity stability. As mobile medical devices shrink in size, manufacturers must prioritize lightweight yet durable connectors to ensure optimal functionality in diverse conditions.

Tip: When selecting interconnects for portable medical devices, ensure they are rated for specific environmental challenges they will face, such as moisture resistance and temperature ranges.

Moreover, as electric vehicles (EVs) surge in popularity, cable assembly designs must adapt to the unique challenges posed by charging solutions. Industry reports show that the EV market has experienced a remarkable growth rate, necessitating connectors that can support rapid charging while enduring harsh outdoor environments. These innovations should include advanced backshell technologies that enhance electrical and mechanical integrity, ensuring that assembly components perform reliably even under stress.

Tip: Incorporate custom designs that address specific environmental conditions to enhance both the performance and reliability of your cable assemblies in the ever-evolving market landscape.

Testing and validation are crucial steps in ensuring optimal cable assembly performance. By implementing rigorous testing methods, designers can identify weaknesses and ensure that the assembly meets the required specifications before it is deployed in the field. Common testing techniques include electrical testing, where parameters such as resistance, capacitance, and insulation integrity are evaluated. Additionally, environmental testing, such as exposure to extreme temperatures or humidity, helps to assess the cable's resilience under various conditions.

Another essential aspect of validation involves mechanical testing, which ensures that the cable assembly can withstand physical stresses such as bending, pulling, and torsion. This is particularly important for applications in demanding environments where cable assemblies may be subject to wear and tear. Techniques such as tensile testing and flexural testing provide valuable data on the assembly's durability. By systematically applying these testing methods, engineers can refine their designs, eliminate potential failures, and ultimately enhance performance and reliability in cable assemblies.

Precision Cable Assemblies

16830 Pheasant Drive

Brookfield, WI 53005

Phone: 262-784-7887

Fax: 262-784-0681