In today's rapidly evolving technological landscape, sourcing high-quality cable assemblies has become paramount for ensuring the reliability and efficiency of a variety of projects across multiple industries. According to a report by MarketsandMarkets, the global market for cable assemblies is projected to grow from $113.5 billion in 2020 to $155.3 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.5%. This surge is driven by increasing demands in sectors such as telecommunications, automotive, and consumer electronics, where the integrity of cable assemblies directly impacts performance and safety. As project managers and engineers seek to optimize their designs with robust connections, understanding the nuances of cable assembly selection, quality standards, and supplier capabilities becomes essential. This guide offers insights and tips to navigate the complexities of sourcing the right cable assemblies for your project needs.

Understanding the various types of cable assemblies is crucial for project success across multiple industries. Cable assemblies can be broadly categorized into categories such as coaxial cables, twisted pairs, and fiber optic cables. According to a report by MarketsandMarkets, the global market for cable assemblies is expected to reach $238.6 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.3% from 2020. This growth underscores the increasing demand for high-quality cable assemblies in sectors such as telecommunications, automotive, and consumer electronics.

Each type of cable assembly serves specific applications and offers distinct advantages. For instance, coaxial cables are highly effective for data transmission in telecommunications due to their superior shielding, which minimizes signal loss. In contrast, twisted pair cables, commonly used in networking, provide good performance at a lower cost, making them the backbone of most local area networks (LANs). Additionally, fiber optic cables, known for their high-speed data capabilities, are rapidly becoming the standard for internet connectivity, which, according to Allied Market Research, is projected to expand significantly, reaching $1.5 billion by 2026. Understanding these types and their unique applications is essential for making informed decisions when sourcing cable assemblies for any project.

When sourcing high-quality cable assemblies for your projects, it is essential to consider several key factors that can significantly impact performance and reliability. First and foremost, understanding the application requirements is crucial. According to a report by MarketsandMarkets, the global cable assembly market is projected to reach $166.6 billion by 2024, driven by increased demand in industries such as automotive and telecommunications. This data underscores the importance of selecting cable assemblies that meet specific electrical and environmental standards, ensuring they can withstand factors like temperature fluctuations and exposure to moisture.

Another critical factor is the selection of materials and manufacturing processes. A study by Grand View Research indicates that the demand for high-quality cable assemblies is closely linked to the quality of raw materials used, with copper and fiber optics leading the market. Assessing the supplier's capabilities in terms of material certifications, production technologies, and quality control processes is vital. It is advisable to collaborate with suppliers who adhere to industry standards like IPC/WHMA-A-620 for cable assembly manufacturing, as this can enhance reliability and minimize the risk of failure in critical applications.

This chart displays the key factors influencing the quality of cable assemblies sourced for various projects. The parameters evaluated include Durability, Flexibility, Cost Efficiency, and Compliance with Standards.

When it comes to sourcing cable assemblies for your projects, understanding the difference between custom and standard options is essential. Standard cable assemblies are pre-manufactured products that are readily available and typically come at a lower cost. They are ideal for applications with common specifications and requirements. For projects that demand speed and cost-effectiveness, opting for standard cable assemblies can streamline the procurement process and help maintain budget constraints.

On the other hand, custom cable assemblies offer tailored solutions to meet specific project requirements. These bespoke assemblies can ensure compatibility with unique components and unique use-cases, which can significantly enhance performance and reliability. While custom solutions typically involve a longer lead time and higher upfront costs, they provide the flexibility to design for specific length, materials, or configurations, ultimately resulting in a more efficient and suitable product for specialized applications. Choosing between these two options depends on the project's budget, timeline, and technical demands, making it crucial to evaluate your needs carefully.

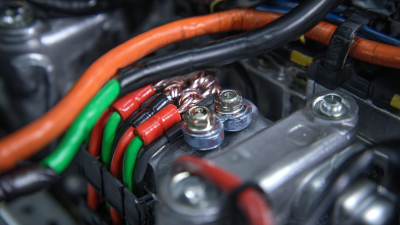

When sourcing high-quality cable assemblies for your projects, understanding the essential materials and components is crucial. The foundation of any reliable cable assembly lies in the choice of conductors. Copper is the gold standard due to its excellent conductivity and flexibility, while aluminum can be a cost-effective alternative for larger applications. Additionally, the gauge of the wire influences the current-carrying capacity, making it important to select the appropriate size based on the specific requirements of your project.

Beyond conductors, insulation materials play a significant role in the performance and longevity of cable assemblies. Polyvinyl chloride (PVC) is commonly used due to its durability and resistance to environmental factors. For high-temperature applications, silicone or fluoropolymer insulations offer superior protection. The choice of connectors is also pivotal; metal connectors provide robust mechanical stability, while plastic connectors might offer lighter weight and corrosion resistance. By carefully selecting these components, you can ensure that your cable assemblies not only meet project specifications but also withstand the test of time.

When it comes to sourcing high-quality cable assemblies for your projects, understanding quality control standards is paramount to ensuring reliability. In recent discussions about offshore wind farms, the importance of robust power cable performance has been highlighted. Failure risks can be significantly mitigated through rigorous testing and adherence to established quality benchmarks. This is particularly crucial in high-demand environments where cable systems must endure both electrical and thermal stresses.

Tips:

- Always verify that your suppliers comply with recognized

quality certifications. This includes ISO standards

and other industry-specific benchmarks that ensure reliability.

- Engage in regular audits and quality assessments of your

cable assemblies to catch potential issues early before

they impact your projects.

Moreover, trends in the solar cable market indicate rapid expansion in this sector. The rise of photovoltaic applications underscores the necessity of high-quality connectors and cables that meet stringent safety and performance standards. Investing in components that are tested for durability and environmental resilience will enhance the overall performance of your energy solutions.

Tips:

- Consider the environmental conditions your cables will face and ensure you select

assemblies that are designed to withstand such extremes.

- Research the latest advancements in cable technology,

focusing on suppliers who incorporate innovative design and manufacturing processes to enhance

product reliability.

Precision Cable Assemblies

16830 Pheasant Drive

Brookfield, WI 53005

Phone: 262-784-7887

Fax: 262-784-0681