In today's technologically driven world, the importance of choosing the right wire and cable assembly for your project cannot be overstated. According to a recent report by MarketsandMarkets, the global wire and cable assembly market is projected to reach $250.6 billion by 2027, driven by advancements in infrastructure and increasing demand for reliable electrical connections across various industries. As projects become more complex, the selection of high-quality wire and cable assemblies that meet specific performance and safety standards is essential.

Whether for industrial automation, telecommunications, or renewable energy applications, understanding the different types of materials and construction techniques available is critical to ensuring optimal functionality and longevity. This guide aims to provide essential insights and best practices to assist you in making informed decisions when selecting the right wire and cable assembly for your needs.

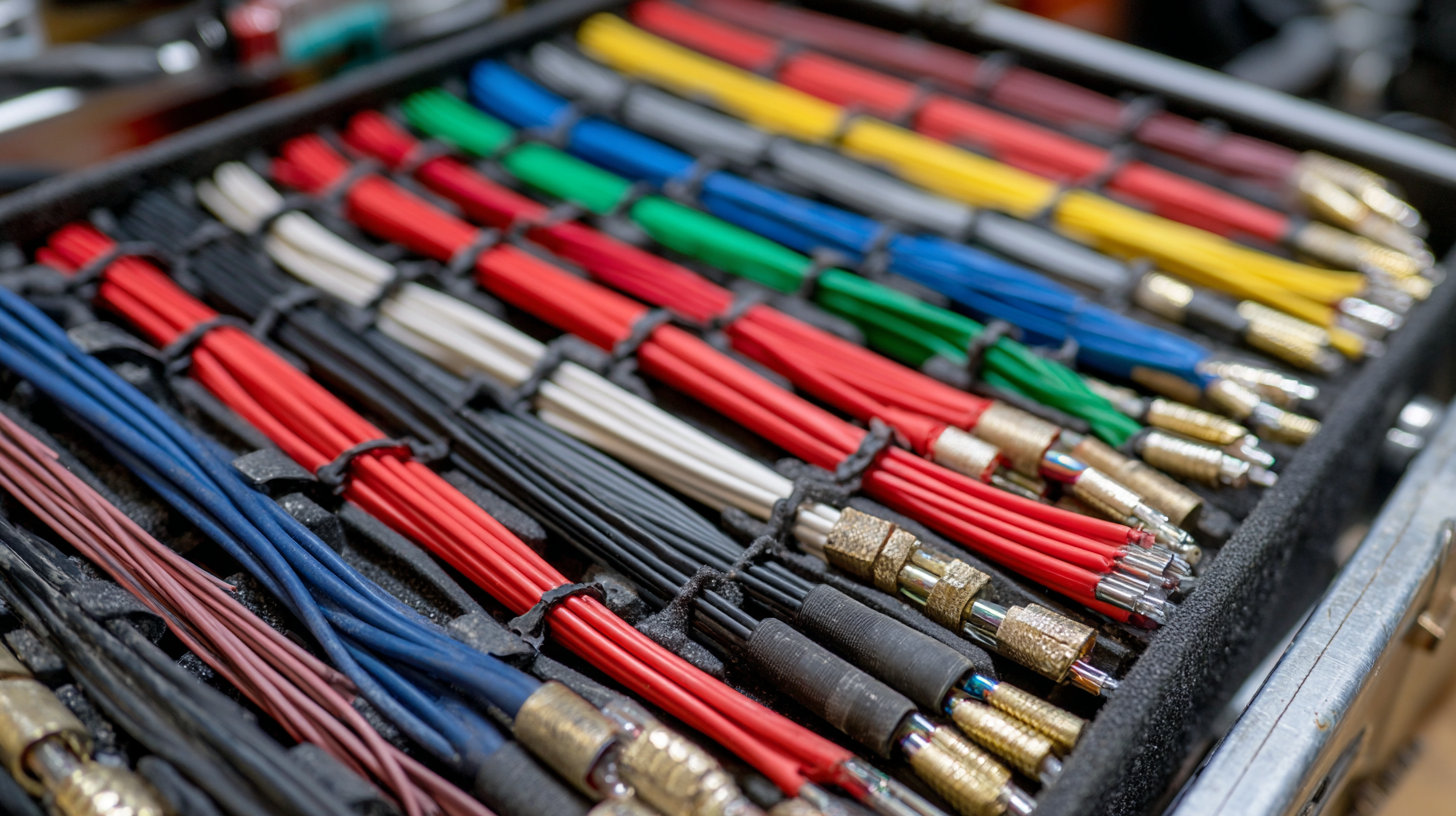

When embarking on a project that requires wire and cable assemblies, it's crucial to understand the different types of options available. Wire assemblies typically consist of multiple wires bundled together, providing a streamlined solution for power and data transmission. By contrast, cable assemblies include connectors at both ends, making them ready to plug and play. Knowing the distinction between these can significantly impact the efficiency and performance of your project.

When selecting wire and cable assemblies, consider the environmental conditions they will be exposed to. For example, if your project is situated outdoors or in a high-moisture area, opting for cables with weather-resistant and UV-stabilized insulation is essential. Additionally, think about the electrical requirements; the gauge of the wire plays a vital role in ensuring safe and adequate current flow.

Tip: Always verify the compatibility of your wire or cable assembly with the rest of your system. Mismatched connectors can lead to performance issues or equipment damage. Also, consider future scalability; investing in higher-quality and versatile assemblies may save costs and headaches down the road.

This chart compares different types of wire and cable assemblies based on their applications and characteristics. The data represents the popularity and usage of various types in electrical projects.

When selecting the right wire and cable assembly for your project, the primary focus should be on identifying your specific project requirements and specifications. Different applications call for varying wire types, which can include considerations such as capacity, environmental conditions, and safety standards. For instance, in modern industrial applications, durability and compliance with industry standards become critical due to the growing demand for reliable power and communication systems. Understanding these requirements can help streamline the decision-making process, ensuring that the chosen assembly meets both performance expectations and longevity criteria.

Moreover, as the industry evolves with advancements in technology, it's essential to stay updated on the latest trends. A focus on energy efficiency and innovation is becoming increasingly important for wire and cable suppliers. This means that industries are leaning towards high-quality, robust solutions that not only fulfill current demands but also anticipate future needs. Therefore, when assessing potential wire and cable assemblies, consider the manufacturer's reputation and their ability to deliver products that align with the latest industry standards and innovations. This informed approach will ensure that your project is equipped with the right tools for success.

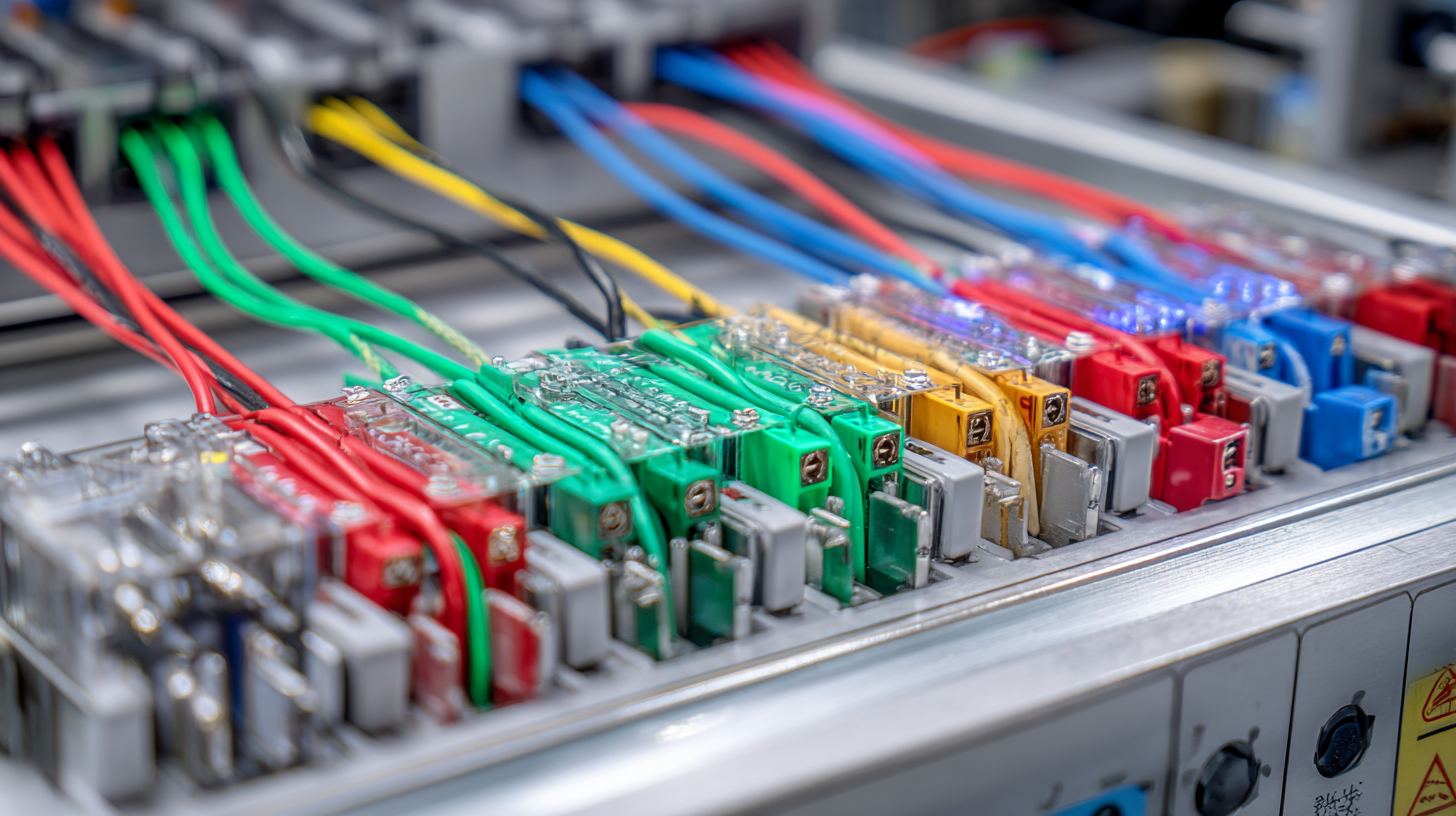

Choosing the right wire and cable assembly for your project is crucial to ensure functionality and reliability. One of the key factors to consider is the application environment. Assess whether the assembly will be exposed to harsh temperatures, moisture, or chemicals. For outdoor or high-stress conditions, opt for cables with durable insulation and protective sheathing to enhance longevity.

Another important factor is the electrical specifications. Determine the required voltage, current capacity, and any relevant standards for your project. It's essential to select wires that can safely handle the expected load without risk of overheating or failure.

**Tip:** Always consult with a manufacturer or supplier to ensure you are choosing the right gauge and type of wire for your specific needs. Consider future scalability as well, allowing for upgrades or expansions without needing complete redesigns. By keeping these factors in mind, you can avoid potential pitfalls and ensure your wire and cable assembly performs optimally in its intended application.

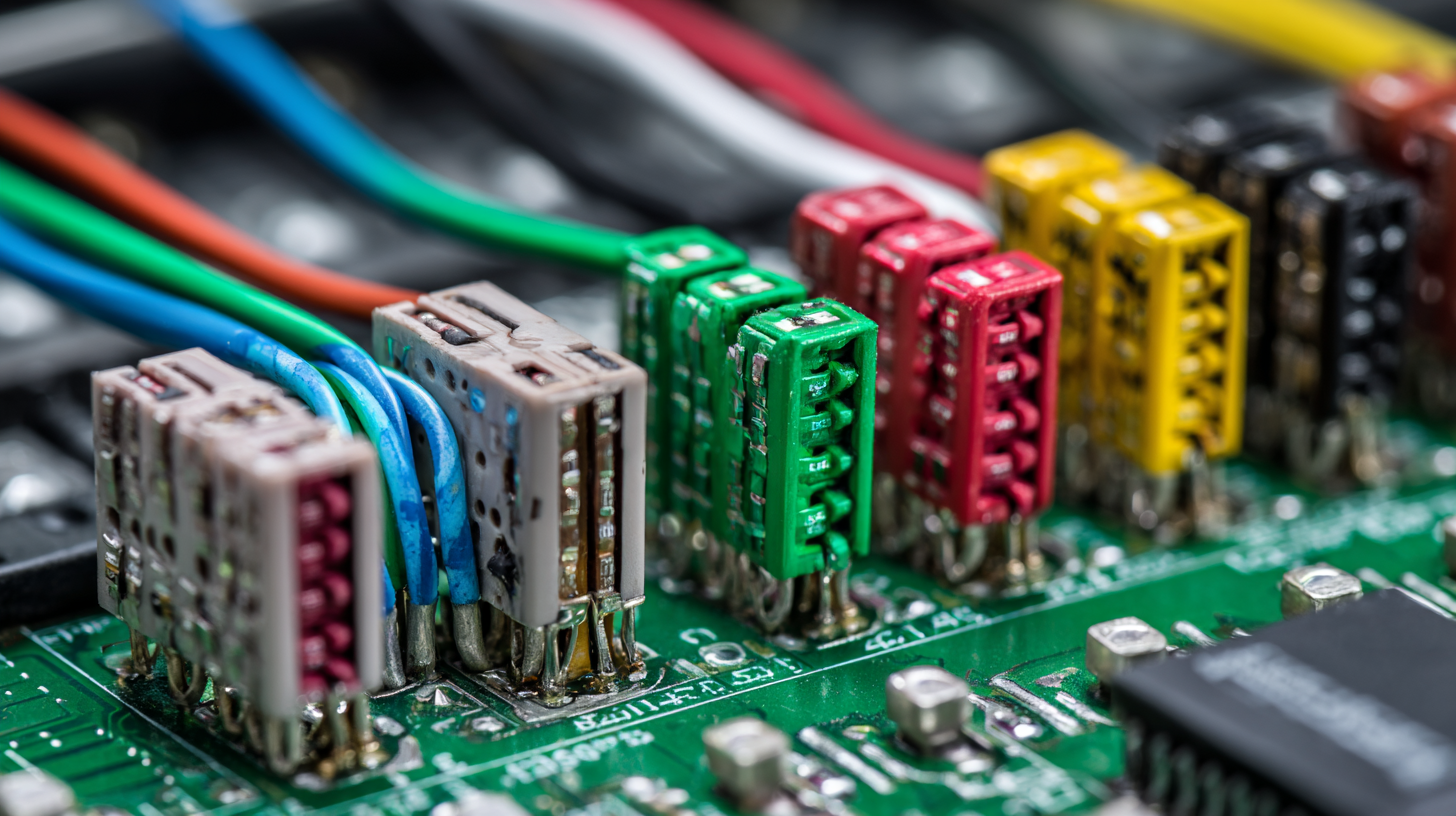

When choosing wire and cable assemblies for a project, it's essential to weigh the benefits of custom versus standard solutions carefully. Standard cable assemblies offer cost-effective solutions and quicker turnaround times, making them ideal for projects with tight deadlines. However, they may not always meet the specific requirements of your application, especially in high-demand environments such as audio recording or telecommunications. For instance, when looking at the latest advancements in microphone cables, it's clear that quality constructions are vital for ensuring high-fidelity sound transmission. These cables, which are often seen as the unsung heroes of audio systems, are typically crafted with materials and designs tailored to minimize noise and distortion.

On the other hand, custom cable assemblies can provide tailored solutions for unique specifications, ensuring optimal performance and reliability. Industries like electric bike manufacturing are seeing a surge in demand for customized connection solutions that prioritize both efficiency and innovation. Data shows that as technology continues to evolve, the need for unique architecture in fiber-to-the-home networks and other applications is becoming increasingly prevalent. By understanding the specific needs of your project, selecting the right type of cable assembly—whether standard or custom—becomes crucial in achieving technical excellence and meeting user demands effectively.

When selecting the right wire and cable assembly for your project, ensuring compliance and safety standards is paramount. Compliance with rigorous safety regulations not only safeguards your project but also enhances its reliability. A recent report highlights that the electrical conduit market in the U.S. is projected to reach $1.72 billion in 2024, growing at a compound annual growth rate (CAGR) of 4.17% during the forecast period. This growth underscores the increasing importance of adhering to quality and safety standards as the market expands.

Furthermore, the JET certification gained by a notable hybrid energy storage system in Japan exemplifies the critical role of rigorous testing and certification processes in ensuring product safety. With the transition to household energy solutions gaining traction, adhering to stringent safety protocols helps build consumer trust and ensures project viability. As the demand for reliable industrial Ethernet networks continues to grow, solutions that comply with relevant safety standards will play a crucial role in maintaining operational integrity in diverse industrial environments. Implementing high-quality cable assemblies not only meets these safety requirements but also boosts the overall efficiency of your systems.

| Wire/Cable Type | Application | Conductor Material | Insulation Material | Voltage Rating | Compliance Standards |

|---|---|---|---|---|---|

| THHN | Building Wiring | Copper | PVC | 600V | UL, CSA |

| XLP (Cross-Linked Polyethylene) | Underground Power Distribution | Aluminum | XLP | 1000V | IEEE, NEC |

| SJT (Service Junior Thermoplastic) | Portable Appliances | Copper | PVC | 300V | UL, CSA |

| MC (Metal Clad Cable) | Commercial Wiring | Copper | PVC | 600V | UL, NEC |

| TPU (Thermoplastic Urethane) | Automotive Applications | Copper | TPU | 60V | SAE, ISO |

Precision Cable Assemblies

16830 Pheasant Drive

Brookfield, WI 53005

Phone: 262-784-7887

Fax: 262-784-0681