In today’s rapidly evolving technological landscape, selecting the appropriate wire and cable assembly for your project is crucial to ensure optimal performance and safety. The global wire and cable assemblies market is projected to reach USD 200 billion by 2026, according to industry reports, reflecting a growing demand across various sectors including telecommunications, automotive, and industrial applications. As the complexity of projects increases, the importance of choosing the right components—tailored to specific voltage, current, and environmental conditions—becomes paramount. This blog will guide you through the essential considerations and best practices for selecting wire and cable assemblies that not only meet technical requirements but also enhance the longevity and reliability of your systems.

When embarking on a project that requires wire and cable assemblies, understanding the various types available is crucial to ensure optimal performance and reliability. According to a recent report by the International Electrotechnical Commission (IEC), the wire and cable market is projected to reach $240 billion by 2026, demonstrating a growing demand for specialized assemblies tailored to diverse applications. This growth is driven by advancements in technology and the increasing need for efficient electrical connectivity across industries such as automotive, telecommunications, and renewable energy.

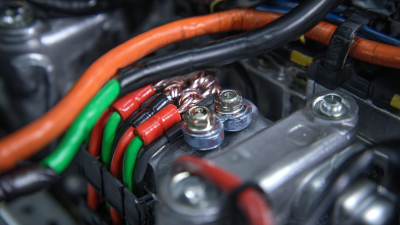

Wire and cable assemblies can vary significantly in design, material, and performance characteristics. For instance, shielded cables are essential in environments with high electromagnetic interference, offering additional protection–a necessity highlighted in a 2022 report from the Institute of Electrical and Electronics Engineers (IEEE), which states that improper shielding can result in data loss and equipment malfunction. Conversely, flexible wire assemblies are preferred for applications requiring movement or bending, showcasing the importance of selecting the right type for specific project needs. By understanding these distinctions and leveraging industry insights, professionals can make informed decisions that align with their project requirements.

When selecting the right wire and cable assembly for your project, understanding key specifications such as voltage, amperage, and temperature ratings is crucial. According to a report by the National Electrical Manufacturers Association (NEMA), improper voltage ratings can lead to overheating and potential failure of the entire electrical system. It’s essential to match the voltage rating of the cable to the voltage requirements of your application, which typically range from low voltage (up to 600V) to high voltage (above 600V), depending on the needs of your project.

Amperage rating is another critical specification, as it determines how much current the cable can safely carry without overheating. The American Wire Gauge (AWG) standard indicates that a 12 AWG wire can handle up to 20 amps for a maximum of 100 feet. However, factors such as the length of the run and ambient temperature must also be taken into account.

Tip: Always check both the wire gauge and the maximum continuous amperage in your application to prevent potential hazards. Additionally, be mindful of the temperature rating; cables are available with ratings from -40°C to 90°C, ensuring they operate safely in various environments. Choosing the right temperature rating can help maintain cable integrity and performance over time.

| Specification | Description | Example Values |

|---|---|---|

| Voltage Rating | The maximum voltage a wire or cable can handle safely. | 120V, 240V, 600V |

| Amperage Rating | The maximum current a wire or cable can carry without overheating. | 5A, 15A, 30A, 50A |

| Temperature Rating | The maximum operating temperature a wire or cable can withstand. | 60°C, 75°C, 90°C |

| Insulation Type | The material used to insulate the wire which affects durability and flexibility. | PVC, XLPE, Teflon |

| Conductor Material | The material of the wire core, determining conductivity and flexibility. | Copper, Aluminum |

When it comes to selecting the right wire and cable assembly for your project, the choice of insulation material is crucial. Insulation not only protects the conductive core but also influences the wire's performance in varying conditions. The most common materials—PVC, Teflon, and rubber—each offer unique properties that cater to different needs.

PVC insulation is widely used due to its cost-effectiveness and versatility, making it suitable for general-purpose applications. However, for projects that require high-temperature resistance or chemical stability, Teflon stands out with its excellent dielectric properties and resilience. Rubber, on the other hand, is favored for its flexibility and durability, making it ideal for environments where cables may be subjected to frequent bending or movement.

When it comes to selecting the right wire and cable assembly for your project, the choice of insulation material is crucial. Insulation not only protects the conductive core but also influences the wire's performance in varying conditions. The most common materials—PVC, Teflon, and rubber—each offer unique properties that cater to different needs.

PVC insulation is widely used due to its cost-effectiveness and versatility, making it suitable for general-purpose applications. However, for projects that require high-temperature resistance or chemical stability, Teflon stands out with its excellent dielectric properties and resilience. Rubber, on the other hand, is favored for its flexibility and durability, making it ideal for environments where cables may be subjected to frequent bending or movement.

Recent analysis of disposable vapes has shed light on the importance of material choice, similar to wire and cable assemblies. In the study, various components were examined, revealing the impacts of different insulation materials on functionality and safety. This emphasizes the need for careful evaluation in projects involving wire assemblies, as the chosen insulation can significantly affect performance and longevity. Understanding the properties of PVC, Teflon, and rubber, and their applications, will ultimately lead you to the ideal solution for your project's specific requirements.

When embarking on a wire and cable assembly project, choosing the right connector type is crucial for ensuring reliable connections and seamless functionality. Connectors play a pivotal role in the overall performance of any system. They not only transfer power and signals but also impact the durability and efficiency of your assembly. Understanding the various types of connectors and their specific applications can help you make informed decisions that align with your project requirements.

Tip 1: Before selecting a connector, assess the environment in which your assembly will operate. Consider factors such as temperature, humidity, and exposure to dust or chemicals. For instance, rugged connectors may be needed for outdoor applications, while standard connectors could suffice for indoor projects.

Tip 2: Compatibility is another key factor. Ensure that the connectors you choose are compatible with the existing components of your system. This includes checking the pin count, size, and locking mechanisms. Mismatched connectors can lead to malfunction and may require costly modifications down the line.

By prioritizing the right connector types tailored to your operational needs, you can enhance the reliability and longevity of your wire and cable assembly.

When undertaking a project that involves wire and cable assemblies, one critical aspect to consider is the cost-benefit analysis between custom and off-the-shelf solutions. Custom cable assemblies, while potentially more expensive upfront, offer the significant advantage of tailored specifications. This can lead to better performance and longevity, particularly in specialized applications where standard options fall short. By investing in a custom solution, you may reduce the need for future replacements and maintenance.

When considering off-the-shelf assemblies, cost efficiency often comes to the forefront. These products are readily available and designed for a wide range of general applications. They usually provide good performance at a lower initial cost and are ideal for projects that have standard requirements or tight budgets. However, it’s essential to assess whether these assemblies meet all your technical needs, especially regarding durability and adaptability.

**Tips:** Always evaluate the long-term implications of your choice. Ask for detailed specifications and performance data to compare with your project's requirements. Additionally, don’t hesitate to reach out to suppliers for advice—they can provide insights based on their experience that might help refine your decision.

Precision Cable Assemblies

16830 Pheasant Drive

Brookfield, WI 53005

Phone: 262-784-7887

Fax: 262-784-0681