In the ever-evolving landscape of technology, enhancing the efficiency and reliability of cable assembly power solutions is crucial for any business that relies on electronic components. The intricate nature of cable assemblies requires a keen understanding of best practices that can optimize performance and longevity. With the right strategies in place, organizations can significantly reduce power losses, improve signal integrity, and ultimately, deliver superior products. This guide will outline the seven best practices for optimizing your cable assembly power solutions, highlighting key considerations that manufacturers and engineers should keep in mind. By implementing these strategies, you can ensure that your cable assemblies not only meet industry standards but also exceed customer expectations in terms of performance and durability.

When it comes to enhancing power efficiency in cable assemblies, choosing the right cable types is crucial. Different cable types have varying capabilities in terms of current handling, voltage ratings, and material composition, which directly affect performance. For example, utilizing high-quality cables that support advanced charging technologies can lead to a more efficient energy transfer, reducing heat generation and energy loss. Additionally, exploring options like gallium nitride (GaN) chargers can optimize charging speeds while maintaining safety, making them ideal for modern electronic devices.

Incorporating the right power supplies is also essential. Whether for gaming PCs or portable devices, selecting units with superior efficiency ratings can greatly impact overall system stability and longevity. This principle extends to power banks as well, where innovative designs ensure that energy is stored and distributed effectively for extended use. As technology continues to evolve, understanding the distinctions between various cables and power solutions will empower users to make informed choices that significantly enhance their power efficiency.

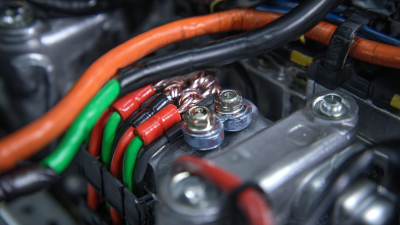

When it comes to optimizing connector designs for maximum current flow in cable assembly power solutions, several critical factors come into play. Notably, according to a report by the Institute of Electrical and Electronics Engineers (IEEE), poor connector design can lead to a 20% efficiency loss due to increased resistance and heat generation. Therefore, ensuring that connectors are designed with high-conductivity materials, such as copper with a nickel plating, can significantly mitigate these issues and enhance performance.

One effective strategy is to select connectors with larger contact areas, which allows for better current distribution and reduces localized heating. Industry standards recommend maintaining a minimum contact force to prevent any loss in performance, ideally within the range of 50-100 grams for standard connectors. Additionally, the choice of insulation material plays a vital role; using thermally stable materials can ensure the connectors withstand higher temperatures without compromising longevity.

To further optimize current flow, incorporate strain relief mechanisms in the design. This not only protects the connection from mechanical stress but also helps maintain effective contact throughout the connector's life cycle. Regular testing and validation of design through thermal imaging can also provide insights into performance enhancement, ensuring energy-efficient transmission in your cable assembly solutions.

Effective thermal management is crucial in optimizing cable assembly power solutions, as excessive heat can lead to decreased performance and reliability. One of the best practices is to incorporate heat sinks and thermal pads in your design. These components help dissipate heat away from critical areas, ensuring that your cable assemblies maintain optimal operating temperatures. Additionally, selecting materials with high thermal conductivity can significantly enhance heat transfer, reducing the risk of hotspots that could compromise functionality.

Another strategy involves designing for airflow. Ensuring proper ventilation around cable assemblies can help facilitate the movement of cool air and the expulsion of hot air. This can be achieved through proper layout and spacing in both your assembly and the surrounding environment. Implementing fans or cooling systems in high-power applications can also bolster cooling efficiency. Ultimately, prioritizing thermal management not only enhances performance but also extends the lifespan of your cable assemblies, making it an essential consideration in the design process.

This chart presents the effectiveness of various thermal management strategies for optimizing cable assembly power solutions. The strategies include heat sinking, thermal interface materials, ventilation, active cooling, cable routing, conformal coating, and proper materials selection.

Automation has become a game-changer in the realm of cable assembly processes, driving enhancements in both accuracy and efficiency. Utilizing automated systems can significantly reduce human error, which often leads to costly mistakes and rework. By integrating advanced machinery equipped with precise measurement and cutting tools, manufacturers can ensure that each cable is assembled to exact specifications, thereby improving overall product quality. Automation not only streamlines the assembly line but also accelerates production cycles, allowing companies to meet increasing demand without compromising on quality.

Automation has become a game-changer in the realm of cable assembly processes, driving enhancements in both accuracy and efficiency. Utilizing automated systems can significantly reduce human error, which often leads to costly mistakes and rework. By integrating advanced machinery equipped with precise measurement and cutting tools, manufacturers can ensure that each cable is assembled to exact specifications, thereby improving overall product quality. Automation not only streamlines the assembly line but also accelerates production cycles, allowing companies to meet increasing demand without compromising on quality.

Moreover, the implementation of automation in cable assembly allows for real-time monitoring and data collection. This capability enables manufacturers to track performance metrics and identify any potential issues early in the production process. With insights gathered from automated systems, teams can make informed decisions to optimize workflows, ultimately minimizing waste and enhancing resource management. As organizations continue to embrace automation, they position themselves to stay competitive in a rapidly evolving market, ensuring their power solutions are reliable, efficient, and cost-effective.

Regular testing and maintenance of cable assembly power solutions are crucial for ensuring reliability and optimal performance. According to a report by the International Electrotechnical Commission (IEC), approximately 30% of electrical failures can be attributed to poor connections and inadequate maintenance practices. Routine inspections and tests, such as resistance measurements and visual checks for wear and tear, can significantly reduce the likelihood of costly downtime and enhance overall system performance.

Precision Cable Assemblies

16830 Pheasant Drive

Brookfield, WI 53005

Phone: 262-784-7887

Fax: 262-784-0681